Kick Warnings Change When Drilling Horizontally In Deep Legacy Formations

By Steve L. Richert

With tremendous opportunities for profit, there is reward for drilling deep lateral wells into formations that previously were drilled vertically. However, drilling unconventional wells into these deep formations (10,000 feet-13,000 feet vertical depth) presents risk that may not be encountered in traditional shale gas and tight oil plays.

Specifically, many of the indicators used to spot a kick do not appear or become so subtle they look like expected behaviors or less dangerous issues. Kicks can be detected while drilling deep horizontals in legacy formations, but to minimize the risk of accidents, the industry needs to become aware of the kick indicators that remain effective and discard the common assumption that a negative flow check means everything’s fine.

Two exemplary formations where more caution regarding kicks may be necessary are the Austin Chalk of eastern Texas and western Louisiana, and the Turner sandstone formation in the Powder River Basin of Wyoming. Opportunities abound in the PRB’s deep wells.

First drilled in the late 1800’s, the PRB has been a prolific producer of oil and natural gas. Vertical wells were drilled into the deeper sections through 1994, when the first lateral well was drilled by Chesapeake Energy. Lateral well drilling did not expand until 2000. The peak push for lateral well development began in 2014 and has continued to gain momentum, with 25,700 permit applications in December 2018, up from the March 2018 record of 10,000 applications.

The oil price crash of 2015 delayed drilling the deep Turner formations because of the higher costs of drilling these wells. Companies placed assets in areas that had more immediate economic returns while awaiting higher oil prices. With those prices experienced for most of 2019, drilling into the legacy formations has picked up.

According to the Wyoming State Geological Society, the Turner sandstone formations “are emerging as one of the most prolific unconventional plays in the PRB of Wyoming. Between January 2017 and July 2018, 21.7 million barrels of oil and 84.3 million cubic feet of natural gas were produced from horizontal Wall Creek or Turner wells.” More than 23% of all oil produced in Wyoming in 2018 came from this reservoir. Many of the wells consistently have exceeded 2,000 barrels of oil equivalent per day.

The productivity of the play’s wells is illustrated by Navigation Powder River (Juniper Capital Advisors LP) Jacob Federal 1-42-73-3H, which had a peak 24-hour production of 2,210 boe (91% liquids). Peak 30-day cumulative production was 60,834 boe/d (92% liquids), for an average of 2,028 boe/d.

Understanding the Risks

There are risks associated with drilling lateral wells, especially deep lateral wells, which may encounter higher pressures with low permeability. These wells present economic risks, in that they are expensive to drill given lost circulation zones and the time it takes to drill to depth. Many companies are accustomed to drilling lateral wells in 7-10 days. These legacy wells take up to 28, and some companies with less aggressive drilling programs drill them in 40 days to mitigate fluid losses into carbonate and other zones.

Safety poses another problem, particularly with well control issues related to kick detection practices associated with deep lateral wells. Recently, the industry has experienced unexpected gas at surface on many locations, blowing flow lines from the BOP, causing the flow line to part, or buck erratically. The challenge is rarely that companies are irresponsible or the crews untrained. The hazard may be applying conventional well control thinking while drilling laterals in deep legacy formations.

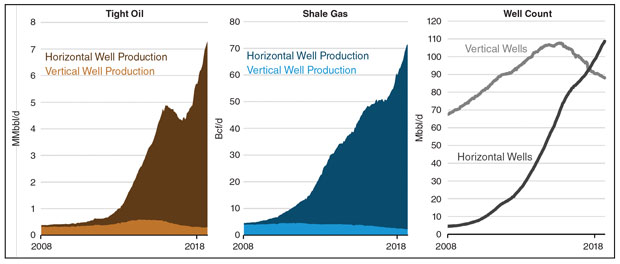

Historically, conventional primary kick indicators have generally related to vertical wells or to gas in the vertical. According to the U.S. Energy Information Administration, from 2004 to 2018, horizontal wells increased in number from 5,000 to 110,000. During the same period, vertical wells increased from 67,000 to 108,000, then declined to 88,000 wells, with most being marginal stripper wells.

In 2004, lateral wells produced 14%-15% of overall oil and gas in the United States. By 2018, those wells produced 96%-97% of all hydrocarbons (Figure 1). Again, from the EIA, “Although horizontal wells have been the dominant source of production from U.S. shale gas and tight oil plays since 2008 and 2010, respectively, the number of horizontal wells did not surpass the number of vertical wells drilled in these plays until 2017.”

In the past two years, there has been a major tipping point in how we drill for and produce hydrocarbons and therefore how we need to approach kick detection. Understanding how kick detection changes is especially important in deep, over-pressured zones because of how gas collects in the well’s horizontal portion and how quickly a blowout can occur if that gas enters the well’s vertical portion.

Per industry recommended practices, conventional kick signs are:

- Increased rate of penetration (ROP);

- Hook load changes resulting from changes in buoyancy when gas is present in the vertical wellbore;

- Pump pressure drop resulting from gas expansion in the vertical;

- Increase in flow or flow with the pumps turned off; and

- Unexplained drilling fluid gains in the active pits.

Pre-kick signs include gas cut drilling fluids, increases in background gas, connection or trip gas, cutting changes at the shakers, drilling fluid temperature increases, and changes in drilling fluid chemistry.

Flow often has been emphasized as the primary kick indicator, with pit gains a distant second. Rig workers are taught that when they think the well is kicking, they should stop and do a flow check. If the well is flowing, shut it in. Many have come to the logical conclusion that if the well is not flowing, there is no kick.

Unfortunately, the current recommended kick detection practices were developed when most wells were vertically drilled. With lateral wells, most of the previously mentioned kick recognition signs and practices may not apply. In fact, until gas is in the vertical, most do not apply. Perilously, if gas has moved to the vertical in a lateral well, the crew and the operation already are in serious jeopardy.

A Cautionary Case History

To understand the potential risks involved, let us examine a lateral well case history.

The planned production zone was tight sandstone with medium to high porosity and low to medium permeability. This formation resembled the Turner sandstone of the PRB Basin in Wyoming.

The crew drilled the vertical section with oil-based mud and was drilling the toe-up lateral section in sandstone with a low viscosity brine at 9.9 pounds per gallon. The well had a true vertical depth of 10,500 feet and a bit-measured depth of 18,700 feet. The casing shoe was set at 9,000 feet TVD/MD. The bit was 6.125 inches in diameter and the drill string was 4.5 inches in diameter.

The morning tour driller had set his pit volume (PVT) alarm at 5 barrels and was showing a drilling rate of penetration of 65 feet/hour. About 10:00 p.m., the PVT alarm activated. Being a careful driller, he pulled up, spaced out, shut off his pumps and executed a flow check (meaning he monitored for flow without pumping). There was no flow. After verifying no one on his crew was moving drilling fluid, he reset his alarm at 5 barrels and continued to drill. After all, no flow means no kick, correct?

Around midnight, the pit alarm activated again. The pits now had an additional 10 barrels of drilling fluid over the mean volume. The driller again did a flow check with negative results. This time, he gave the well a full 30 minutes to flow. While waiting, he checked the PVT tracking system to make sure everything was working correctly. It was, and for the second time, the well did not flow. Again, if a well does not flow, there is no kick, right?

Resetting his PVT alarm for 5 barrels, the driller continued to drill. At 2:00 a.m., the PVT alarm activated a third time. The driller ceased drilling, spaced out, and checked for flow. There was none, but fortunately, he was disconcerted enough to shut the well in and wake the company representative.

The company representative decided to give the well time to talk to him. After about 60 minutes, the casing gauge began to move and eventually stopped at 800 psi. The well definitely was kicking. It took 10 days to sweep the gas out of the lateral with high viscosity/high lost circulation material sweeps.

What was happening in this well and why did the driller not see any signs of a kick other than pit gains?

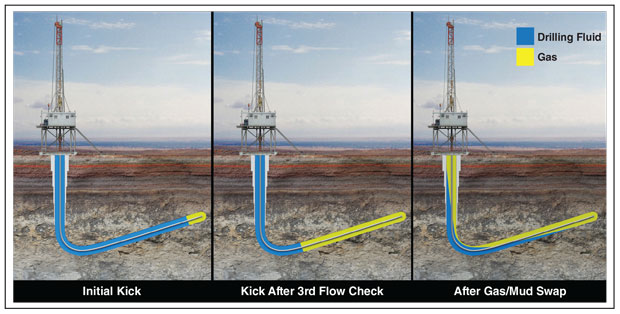

Because the formation was a tight sandstone, much of the gas seen at surface was drilled gas. However, the bit encountered a section of more porous rock with embedded methane gas. The sandstone had low permeability, so the gas entered the well slowly, filling the lateral. With a toe-up configuration, the gas migrated to the highest point, at the bit (see Figure 2, Initial Kick).

As the driller continued to drill, the wellbore continued to fill with gas, causing the PVT gains (see Figure 2, Kick After 3rd Flow Check). At this point, the driller shut the well in, and it took some time for the low permeability formation to develop wellbore pressure against the shut-in annulus.

If the driller had continued to drill, assuming no flow meant no kick, he eventually would have filled the lateral wellbore with gas. If the gas had turned the corner into the vertical, the drilling fluid in the annulus would have U-tubed into the toe-up lateral section. The height of the drilling fluid in the vertical and thus the hydrostatic pressure would have dropped instantaneously, as the differing densities between the gas and drilling fluid swapped places (see Figure 2, After Gas/Mud Swap).

The swap of fluids and subsequent U-tubing of the annulus drilling fluid would have happened in seconds. With gas at or near surface, the well likely would have unloaded and blown out.

Important Lessons

What can be learned from this case history? When drilling laterals into deep formations that traditionally were drilled vertically, conventional thinking about well control in unconventional formation lateral well drilling can result in disaster. In this case, the only clear indicator of a kick was PVT volume gains. None of the others showed.

Many kicks in lateral wells do not flow because of low permeability. When lateral wells do flow, it looks like the well is ballooning, that is, with very minimal flow. The ROP, hook load and pump pressures do not change significantly as they do in vertical wells.

The pre-kick signs sometimes do not show with lateral wells. The drilling fluid may be gas cut because of drilled gas, or show minimal background gas, so crews do not pay much attention to gas concentrations unless they change significantly. Cuttings remain generally the same as the lateral is drilled because the drilling program follows the formation. Porosity changes are subtle if they happen at all, so ROP may not be a reliable kick indicator. With most lateral wells, pit volume is the only accurate kick indicator in the lateral portion.

This case history offers several lessons. First, drillers need to be empowered to shut the well in when they think the well is kicking, even if there is no flow. As the case study showed, a well may be kicking to the point of serious consequences and never present a positive flow check.

Second, when consolidated gas moves into the vertical section of the well unnoticed, even if there is not the dramatic U-tube effect of the drilling fluid seen in the case history, the gas expands rapidly. In fact, with every one-half of the distance to surface, with uncontrolled expansion, the gas doubles in size.

To put that rapid expansion in perspective, if a 2-barrel kick enters the well’s vertical section at a depth of 10,000 feet, at 5,000 feet, the gas volume will be 4 barrels. By 2,500 feet, it’ll reach 8 barrels. At 1,250 feet, it’ll be 16 barrels. By 625 feet, the volume will be 32 barrels. When gas reaches 625 feet, there are only 19 barrels of available annulus space with a .0301 barrel/foot annulus capacity. At that point, the gas poses a credible risk to the crew and assets at the well site.

If the driller stops to do a flow check early when gas is in the vertical, he may see minimal or no flow because of the formation’s low permeability; any flow seen would be gas expansion. In many cases, the flow will look like ballooning (see Ballooning Perception May Be Flawed, AOGR, April 2019). Because most of the other standard kick signs may be difficult to detect, we need to consider PVT gains the primary kick indicator, especially when drilling deep, unconventional lateral wells.

Steve L. Richert is manager of instructor and course development at Wild Well Control in Houston, where he leads education and development for well control instructors, including knowledge progression, certification, and course creation and refinement. He has 20 years of industry experience, coupled with a 20-year adult education background focusing on how humans acquire knowledge. Richert joined Wild Well Control in 2012 after serving as a driller at Ensign Energy Services, and as a financial specialist at U.S. Bank and TD Ameritrade. He studied mechanical engineering at the University of Oklahoma and holds a B.A. in history and philosophy from Grace University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.