Balancing Intelligent Automation, Real-World Operational Physics Key to AI-Based Optimization

By Brandon Brown

The oil and gas industry was employing artificial intelligence long before ChatGPT or Microsoft Copilot became part of the public consciousness. In fact, the term “digital oil field” was coined 25 years ago to describe the application of a category of precursor digital technologies that we now collectively recognize as early-generation artificial intelligence. With such a long pedigree compared to many other industries, one might expect AI to be at a relatively advanced implementation stage in oil and gas. That, however, is not the case.

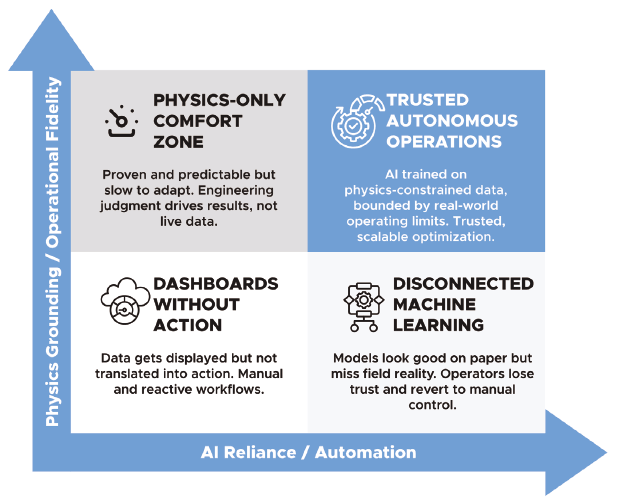

Practical, effective AI has been promised for years to oil and gas producers, but most operators are still stuck in first gear with the rewards of the digital oil field remaining elusive for many. Too often, pilot projects have stalled, legacy consultants have recycled old ideas, and digital dashboards have collected dust. When digital efforts fall short, companies tend to retreat to physics-only solutions, relying on manual calculations and engineering judgment without the benefit of data-driven intelligence.

At the other end of the spectrum, AI-only approaches produce outputs that look rational on paper but often clash with actual field experience.

The problem is not technology—it is adoption, alignment, and trust.

The Operator’s View

The perceived merits of AI-driven solutions can admittedly vary based on the eye of the beholder, but from the perspective of my time sitting in the operator’s seat as part of a team that spent years leading one of the most respected digital transformations in the Permian Basin, there is no disputing that AI can be a powerful competitive difference maker. It delivered measurable production gains, extended equipment life, and positioned the operating company as a digital leader among its peers.

Most oil and gas AI applications use pattern recognition models to spot correlations and generate forecasts that look good on paper but often clash with historical field experience, making them easy for operators and engineers to ignore. The opposite extreme is physics-only solutions that rely on equations and design assumptions that cannot keep up with real-time variability. The ideal is to build every model on ground truths using the physics that govern oil field behavior, then continuously refine and update those models with live data to remain in the sweet spot between engineering rigor and intelligent automation.

I walked away from that experience with a clean slate but hardly empty handed, carrying forward years of experience building, testing, and deploying solutions inside operating companies. I had witnessed the many positives of AI but also saw the ceiling. Progress stalled when alignment faltered, and potential was left on the table. That is why I decided to make the leap from operating company to technology startup—to build AI differently with operations at the center from the very start.

Instead of retrofitting old tools or forcing legacy software into new clothes, the challenge is to rebuild with the oil field in mind, grounding every model in both operational dynamics and hard-and-fast tenets of physics while shaping it with real-world data. The core technological capabilities behind AI are fairly universal, but how they are deployed has everything to do with the ultimate value they can deliver in oil and gas production operations.

The Ideal Approach

Most oil and gas AI applications can be characterized as pattern recognition, a function of machine learning. The models spot correlations and generate forecasts that look good on paper but often clash with historical field experience. When a recommendation does not line up with what operators or supervisors expect, the model gets ignored as implausible. The opposite extreme is no better. Many companies fall back on physics-only solutions, relying on equations and design assumptions that cannot keep up with real-time variability. Either approach, on its own, leaves gaps.

The core technological capabilities behind AI are fairly universal, but how they are deployed has everything to do with the ultimate value they can deliver in oil and gas production operations. Shown here, AI-controlled chemicals optimization for a multiwell pad matches dosing to dynamic well conditions to avoid the unnecessary expense of overtreatment on one hand and the operational risks of undertreatment on the other.

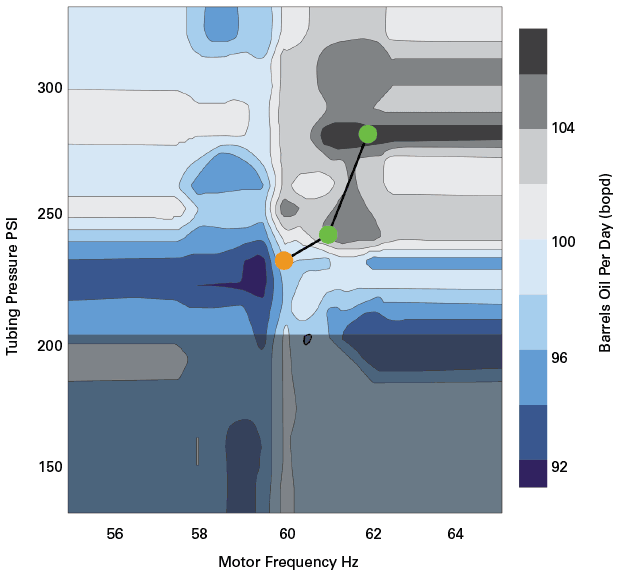

The ideal is to build every model on ground truths using the physics that govern oil field behavior, but also continuously refine and update with live data. Whether optimizing pump speeds, managing tubing pressure within electrical submersible pump systems, or improving chemical usage, the system learns every single second from data but remains constrained by the same principles production engineers use to design artificial lift systems.

That foundation makes the models more trustworthy. They do not just predict outcomes but also behave in ways operators, supervisors, and engineers already understand and inherently recognize. Instead of asking teams to abandon their instincts, the system validates them and earns the right to be taken seriously.

To support adoption, our approach is designed in a phased framework:

- Level one provides visibility and suggestions;

- Level two enables semi-automated decisions with supervisor oversight; and

- Level three moves to full autonomy when teams are ready.

By giving operators, supervisors, and engineers control over the pace, confidence builds naturally. Adoption grows not because it is forced, but because the results make sense in the real world.

The Right Targets

For operators and supervisors, success is measured in uptime, pump life, and how often they have to roll a truck to a wellsite. Adoption takes hold only when AI helps them hit the targets that matter most:

- Fewer truck rolls. Automated chemical monitoring and backpressure control reduce unnecessary trips, freeing time for higher-value work. Instead of spending hours on the road, teams can focus on preventive maintenance, troubleshooting, and high-priority wells. In some cases, entire service routes can be consolidated, saving fuel, reducing wear on vehicles, cutting overtime costs, and reducing risk exposures.

- Cleaner run time data. Reliable signals make setpoint decisions easier and faster for operators, supervisors, and engineers. Instead of piecing together inconsistent data from multiple sources, they can access a single, trusted view of well performance. Over time, as confidence grows, the system moves toward full autonomy. The technology fades into the background, making adjustments automatically, while the field focuses on higher-value tasks. The result is not just cleaner data, but smoother operations that require less manual intervention.

- Longer pump life. Extending ESP run time by 30%-50% means fewer interventions and less downtime. Every avoided pull saves significant cost and prevents lost production. For supervisors, that means fewer phone calls in the middle of the night. For operators, it means fewer disruptions to their daily workflow. For engineers, it provides confidence that designs are being executed as intended.

- Stronger key performance indicators. More consistent production makes it easier for teams to meet performance metrics and for engineers to support quarterly results. For many supervisors and managers, these improvements directly impact incentive pay and bonus structures, turning adoption into a personal win as well as a business one.

When adoption happens at the field level, the cultural shift becomes visible. Operators stop waiting for failures and start anticipating them. Supervisors use data to validate instinct instead of working in isolation. Engineers build more confidence in forecasts because they know the field is using the system. That is when transformation moves from a pilot project to a daily habit.

The Scale Up

We started small. Chemical tank automation delivered immediate savings by reducing overtreatment, cutting unnecessary truck rolls, and improving treatment accuracy with real-time data. It was simple, visible, and easy to trust, a first step that proved the system worked in the field. From there, we applied the same physics plus AI framework to ESP optimization. By managing tubing pressure within ESP systems, stabilizing run time, and dynamically adjusting setpoints, we improved efficiency and extended pump life by up to 50%. Production rose consistently, downtime fell, and crews saw the results on their own wells.

An AI foundation that balances engineering rigor with intelligent automation makes models trustworthy and ensures that they behave in realistic ways that operators, supervisors, and engineers understand and inherently recognize, whether commissioning edge computing hardware for remote monitoring and optimization of ESP performance (as shown here) or installing digital controls to automate chemical dosing based on live operational data.

This same approach is now being prepared for other optimization challenges, showing that the framework is adaptable across operations. Adoption spread not because it was mandated, but because the results were clear and compelling for everyone in the chain of command.

The lesson from early deployments was simple: when the approach is grounded in physics, informed by data, and built for the field, scaling becomes natural. Our modular design now brings new wells and workflows online at scale. “ESP optimization in a box” is one example, but the same principles apply to chemical management and other areas where optimization was once too complex or too slow. Physics-only models cannot deliver this adaptability, and data-only models cannot deliver the trust. Together, they create systems that improve with every deployment.

The latest version includes a redesigned user interface built around how operators and supervisors work, with engineers able to dive deeper as needed. It is efficient, commercial grade, and focused on usability. The system learns from each well, refining recommendations in real time and delivering more value with every step. Momentum is building across operators. The focus is no longer on pilots, but on scaling proven outcomes quickly and consistently across multiple domains.

The Real Challenge

The hardest part was never the models. It was always the people. Operators were stretched thin, supervisors were cautious, and engineers were skeptical because too many new solutions ignored the classical physics foundation of their training. Resistance rarely came as loud opposition. It showed up quietly, waiting it out, sticking with familiar workflows, or questioning whether the effort would fade like the others. Building trust was the first step. Once recommendations matched instincts and respected operational constraints, adoption followed. But trust alone was not enough. There were moments when progress stalled, and the easier path was to back off. In hindsight, we learned that was a mistake. When resistance surfaces, it is often a sign the work is pressing on something that matters.

AI-based ESP optimization continuously fine-tunes pump speed and tubing pressure to keep wells in their most favorable operating windows without human intervention. A strategic approach to applying AI technology uses a phased framework that starts with operational visibility and suggestions, progresses to semi-automated decision-making with supervisory oversight, and then moves to full autonomy only when teams are ready to maximize the benefits of AI in production operations.

Another barrier was ownership. Too often, the business expected the information technology department to design, deliver, train, and continue owning the solution. That expectation was never realistic. For transformation to stick, IT may spark the effort, but the business must take ownership. Workflows have to evolve and decision making has to shift. Without that baton pass, the effort never moves past the “science project” stage.

What separates success from failure is leadership resolve. When leaders hold the line, solutions survive long enough for operators and supervisors to see value in the field. Once uptime improves, truck rolls drop, KPIs move in the right direction, and skepticism fades. Without that resolve, the tools never reach the point where the field can embrace them, and adoption gradually slips away. The companies that succeed are not the ones with the most dashboards. They are the ones with the most resolve and the leadership willing to push through resistance and keep the effort moving when it matters most.

The industry does not need more digital theater. It needs execution. And it needs solutions that adhere to physics and become stronger with every shred of new data so they can be trusted in the field. That is the only way AI can meaningfully reduce truck rolls, improve pump longevity, and help teams hit the targets that matter most. The approach works because it is practical, transferable, and designed around how operators, supervisors, and engineers actually work.

What comes next is not more pilots, but scale. Adoption takes root when leaders provide the resolve and the field sees the results. Physics-only solutions are too rigid, and AI-only solutions are too detached. Progress comes from both working seamlessly together. The models are ready. The foundation is set. The only question is, who is ready to lead?

BRANDON BROWN is co-founder and chief executive officer of ROAM-AI, where he drives the company’s vision, strategy, and growth in AI-driven artificial lift optimization. With more than 20 years of experience in digital transformation, AI, and enterprise IT leadership, Brown has built and led high-performing teams that deliver advanced technology solutions to complex industry challenges. With the belief that data is the foundation of modern decision-making, he has dedicated his career to helping organizations transition from instinct-driven to data-driven operations to unlock efficiencies and competitive advantages. Before co-founding ROAM-AI, Brown served as vice president and chief technology officer at Vital Energy and as director of intelligent operations at Chesapeake Energy. He holds a bachelor’s from Northeastern State University and an MBA from Pepperdine University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.