Illinois Basin Applications Demonstrating Potential Of ASP EOR Technology

By Sinisha “Jay” Jikich, John Grube, Beverly Seyler, Nathan Webb and James Damico

CHAMPAIGN, IL.–The Lawrence Field in the Illinois Basin has produced in excess of 410 million barrels of oil since 1906 through primary and secondary waterflood techniques. Today, the field is producing at less than 2 percent oil cut, and like many mature fields in the United States, is approaching its economic limit, even though there is much remaining recoverable oil.

Reservoir characterization research at the Illinois State Geological Survey (ISGS) and the National Energy Technology Laboratory under a grant from the U.S. Department of Energy is supporting pilot and expansion areas for implementing alkaline-surfactant-polymer (ASP) floods in two distinct sandstone reservoirs in the Lawrence Field.

As operator of the field, Rex Energy Corporation has committed resources to implement ASP floods in the field, and the research conducted by the ISGS is intended to optimize the opportunity for success of this project. Rex Energy owns and operates 21.2 square miles in the Lawrence Field, and its properties account for 85 percent of the field’s total gross production.

Using ASP core flood test results, it is estimated that 130 million barrels of the original 1 billion barrels of oil in place can be recovered using ASP in reservoirs in the Lawrence Field. ASP flooding is an untested technology in the Illinois Basin, and this project presents an exceptional opportunity to perform and document field testing of this unconventional recovery technique on two of the most prolific reservoirs in Illinois.

Similar reservoirs in the Lawrence Field increased production from 1 percent to 20 percent oil cuts with more than 450,000 barrels of oil produced from a 25-acre pilot during an earlier surfactant-polymer flood conducted by Marathon Oil Company. ASP technology may be a more cost-effective technology for improving recovery from mature and shallow oil fields in the Illinois Basin than the earlier tests.

ASP Technology

The alkaline-surfactant-polymer technology recovers incremental oil by co-injecting interfacial tension reduction agents (alkali and surfactant) with a mobility control agent that improves flood sweep efficiency (polymer). Alkali (NaOH or Na2CO3) and surfactant alters the relative permeability curve through three primary mechanisms: interfacial tension reduction, oil solubilization, and wettability alteration.

Adding alkali converts acids in the oil to soaps and makes more favorable conditions for surfactants. Interfacial tension reductions in excess of 10,000-fold have been observed when alkali and surfactant are blended, while either agent alone had, at best, 10- to 20-fold interfacial tension reductions. Alkali will reduce surfactant and polymer adsorption when co-injected. Polymer and surfactant affect each other’s adsorption as well as interacting on a fluid-fluid basis.

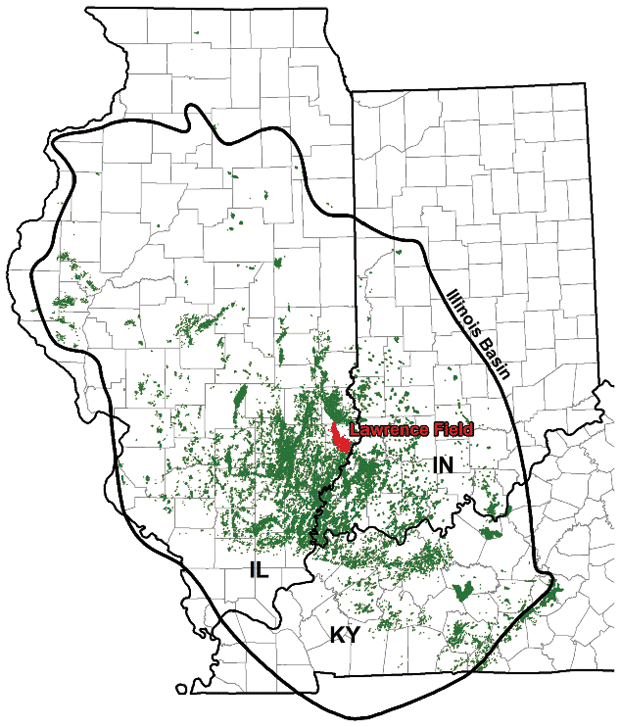

Most of the unrecovered oil in the field, located in Lawrence County, Il. (Figure 1), is contained in Pennsylvanian-age Bridgeport sandstones and Mississippian-age Cypress sandstones. These reservoirs are highly complex and compartmentalized. Detailed reservoir characterization, including the development of 3-D geologic and geocellular models of target areas in the field, is needed to identify areas with the best potential to recover remaining reserves, including unswept and bypassed oil.

This four-year project was designed to compile, interpret and analyze the data required to conduct reservoir characterization for the Bridgeport and Cypress sandstones in pilot areas as well as expansion areas for broad fieldwide implementation of ASP flooding in the Lawrence Field. Geologic and geocellular modeling needed for reservoir characterization and reservoir simulation were completed as prerequisites for designing efficient ASP flood patterns.

Characterizing the complex reservoir geology that identifies the geologic conditions that will optimize oil recoveries for expanding the ASP flood from small, limited pilots in the Bridgeport and Cypress sandstones to the remainder of Lawrence Field is the primary objective of this project. It will permit the evaluation of the oil recovery efficiency from Bridgeport and Cypress sandstone reservoirs using ASP technology. Additional objectives of this project include assessing the applicability of ASP flood technology to similar reservoirs in the Illinois Basin and other U.S. reservoirs.

Reservoir Characterization

The geologic and geocellular modeling needed for reservoir characterization and reservoir simulation were completed as prerequisites to designing efficient ASP flood patterns. This work identified the reservoir characteristics that were required for developing an effective strategy for expanding from pilot areas to full-field implementation of ASP flooding.

A major task involved compiling databases pertinent to completing reservoir characterization of pilot and expansion areas, and is now completed with the exception of newly generated data and newly available data. Detailed digital cross-sections were completed for each of the pilots; available core were described, digitally photographed and interpreted. Facies were described and identified on electric logs.

Petrographic analyses, including thin sections, scanning electron microscopic and X-ray diffraction analyses of selected samples were used for reservoir descriptions. Reservoir sandstone compartments have been mapped. Cross-sections containing interpretations of sequence stratigraphic concepts were constructed. This information was incorporated into 3-D digital geologic models and 3-D digital geocellular models of the two pilot areas.

Another important task consisted of constructing fieldwide cross-sections and contoured structure maps to assist in identifying expansion areas requiring detailed reservoir characterization ahead of implementing ASP flooding beyond the pilot areas. Detailed reservoir characterization was upscaled from the pilot areas to incorporate more than six square miles. Every effort was made to study in detail those areas best suited to Rex Energy’s strategy for broader application of ASP flooding. A final task is assessing ASP flood opportunities in large mature fields in the Illinois Basin as well as nationwide.

Data from the 25 largest Cypress and Pennsylvanian fields in Illinois have been collected and formatted into tables to assess ASP flood technology in this region. The parameters needed for ASP floods have been assembled for several of the larger fields in Illinois, including the Louden Field in Fayette County, a 385 million-barrel field. The success of ASP flooding in Pennsylvanian Bridgeport B sandstone reservoirs in pilot areas of the Lawrence Field suggests that ASP technology can be successfully applied to similar reservoirs throughout the Illinois Basin.

Major Differences

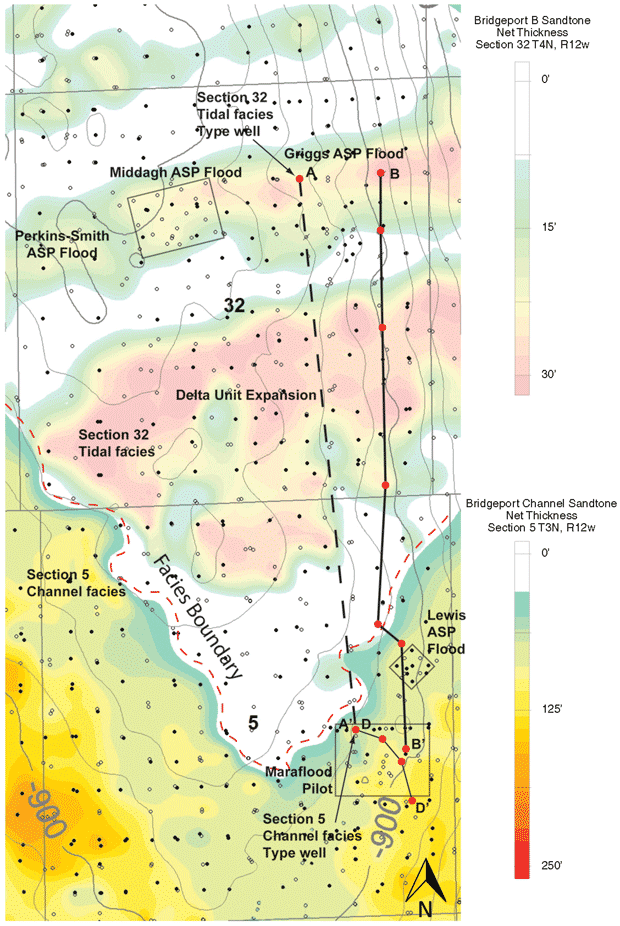

This article highlights the results from Section 32 T4N R12W and Section 5 T3N R12W of Pennsylvanian-age Bridgeport B sandstones, and changes in reservoir character. Bridgeport B correlative sandstones in Section 5 T3N R12W were the site of an ASP pilot as well as an earlier successful Maraflood project. The Bridgeport B sandstone in the Middagh Lease of Section 32 T4N R12W is an active ASP flood. Figure 2 shows a map of the Bridgeport ASP pilot in Section 5 and the ASP expansion area in the Middagh Lease in Section 32.

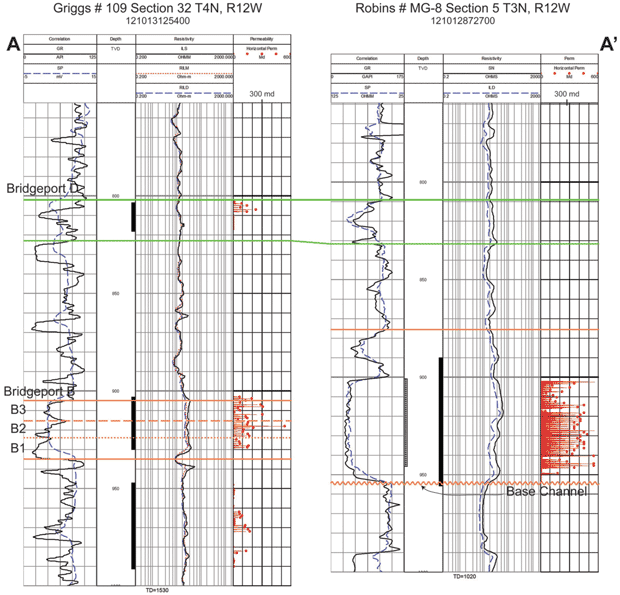

As the cross-sections show, there are major differences in the reservoir characteristics of the Bridgeport sandstones between these two ASP flood areas. These differences are illustrated in the two end-point wells in the A-A’ cross-section in Figure 3. The Bridgeport B sandstone has been informally subdivided into three subunits (B1, B2 and B3) in Section 32 T4N R12W and the north-central portion of Section 5 T3N R12W. The well on the left is the Griggs No. 109 in Section 32 and on the right is the Robins No. MG-8 in Section 5.

Bridgeport sandstones in Section 32 commonly show a stacking of up to three lenses, while the sandstones in Section 5 are characteristically thick and blocky channel fill. Core-measured permeability is plotted in red on the right side of each log with a scale of 0-600 milliDarcies. Average core-measured permeability in Section 5 sandstone is 314 mD, compared with Section 32, where the average permeability is 113 mD. Recognizing and understanding changes in permeability and porosity throughout the reservoir is important in delineating flow units, understanding channeling of reservoir fluids, and determining remaining recoverable oil.

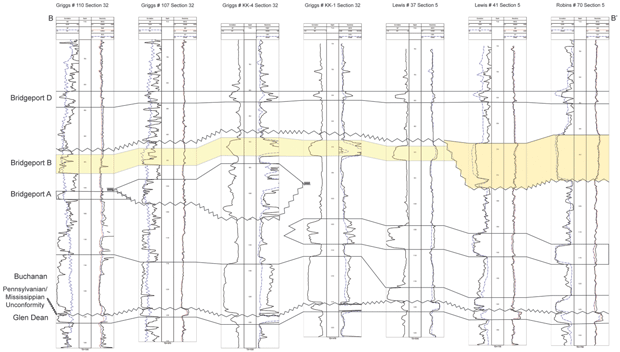

Understanding characteristics related to the depositional environment and examining the clay mineralogy as well as taking a close look at the petrography of the sandstone can go a long way toward explaining these pronounced differences in permeability. These wells are about 1.25 miles apart, but it is common to see this rapid change over only a few hundred feet, as is shown in cross-section B-B’ in Figure 4.

FIGURE 4

Cross-Section B-B’ Showing Relationship of

Pennsylvanian-Age Bridgeport B Across Sections 32 and 5

The north-to-south cross-section B-B’ shows channel fill sandstone and nonchannel fill tidally influenced sandstone deposits in the Bridgeport A and B intervals from Section 32 T4N R12W to Section 5 T3N R12W. This cross-section connects the 1980s Maraflood pilot and a recently completed ASP pilot in the channel fill sandstone in Section 5 with the tidally influenced sandstone deposit of the Bridgeport B in Section 32, where ASP flood development is in progress.

Depositional Environment

Sandstones in Section 5 T3N R12W initially were deposited in a fluvial channel, but continuous transgression led to a change in the environment to tide-influenced coastal and estuarine. Thick sandstones in Section 5 were deposited initially in an incised channel with the lower erosive contact, tabular cross-bedding and indistinct zones being part of the fluvial facies. Sea level transgression occurred during sedimentation within the incised channel, resulting in a change in facies from fluvial to coastal marine-estuarine sandstone deposition. The thick sandstone body in Section 5 becomes more ripple bedded with flaser and lenticular bedding near the top, indicating the transition from fluvial facies to coastal/estuarine facies.

The abundance of replaced plant material and spores in the lower fluvial facies of the Section 5 sandstone may indicate that the muddy area surrounding the estuary was a lycopod swamp. As the sea level continued to rise, the incised channel widened upward until the estuary finally overran the banks of the channel and embayed the entire area of interest.

The thinner sandstone reservoirs in the Bridgeport B interval of Section 32 T4N R12W were deposited in a tidally influenced coastal/estuarine environment. These sandstones are finer-grained and more compacted, and therefore, less porous and permeable than the channel fill reservoir sandstones in Section 5 T3N R12W. Tidal flat, intertidal flat, tidal sand bars and tidal estuarine deposits are located in Section 32. Tidal indicators in the sandstone in Section 32 include ripple bedding, flaser and lenticular bedding, tidal rhythmites and tidal couplets. Some burrowing trace fossils also can be observed.

Many of these features are also observed in the uppermost portions of the channel fill sequence in Section 5. Several still stand and channel fill episodes are observed in Bridgeport units in the area of interest. The complexity of this depositional system illustrates the need for detailed mapping of individual sandstone reservoirs, and also explains the high degree of variability in reservoir characteristics and geometries over a small area. Understanding this complexity is necessary for successful EOR development.

Reservoir Mapping

An isopach map of the net sandstone of the Bridgeport B in Section 32 T4N R12W and the thick correlative Bridgeport channel sandstones in Section 5T 3N R12W are shown Figure 2. As illustrated in the B-B’ cross-section in Figure 4, the Bridgeport B in Section 32 occupies the same stratigraphic position as the thick sandstone in Section 5. In Section 32 T4N R12W, the Bridgeport Sandstone is mapped with a two-foot contour interval with the warmer colors representing thicker sandstone (Figure 2). In Section 5 T3N R12W, the Bridgeport Sandstone is mapped using a 10-foot contour interval with the warmer colors representing thicker sandstone.

Reservoir sandstone in the northern half of Section 32 trends east-to-west, and while the sandstone in the southern half of the section takes on a triangular shape, the overall trend is predominately east-to-west. This triangular Bridgeport B region is bounded by two thick sandstone bodies that trend into Section 5 T3N R12W from the northeast and northwest, and converge in the southern part of the section. Thicknesses of these blocky sandstones range up to »170 feet.

These thick sandstone bodies that appear correlative to the Bridgeport B are actually channel fill deposits that are related to a sea level drop and erosion of the Bridgeport B sequence, following deposition of the Bridgeport B and are, therefore, younger reservoir strata than the Bridgeport B reservoirs. This sequence stratigraphic complexity is prevalent throughout the Pennsylvanian rock section in the Lawrence Field, and is a reservoir characteristic component that must be understood for effective ASP implementation.

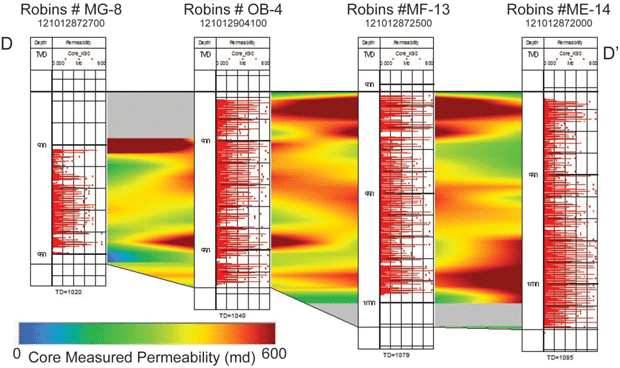

A cross-section grid was constructed in the eastern part of Section 5 T3N R12W using all available wells with core-measured porosity and permeability values. Most of the core-measured porosity and permeability values are from thick channel fill sandstones. This is the same area as the 1980s Maraflood pilot and the recently completed ASP pilot. The cross-section D-D’ in Figure 5 shows core permeability values interpolated between the wells, indicating the presence of flow units in the sandstones with higher permeability and porosity.

Warmer colors in the right section are areas of higher permeability (600 mD) and cool colors are areas of lower permeability. These cross-sections show some well-to-well continuity of very high permeability and porosity values, indicating a strong likelihood of channelized flow in this reservoir unit. It is difficult to correlate preferential flow units within the channel facies reservoirs with standard mapping techniques using the older-style spontaneous potential (SP)/electric logs that are principally available throughout Lawrence Field. Recent log suites and core information have greatly enhanced the ability to delineate reservoir characteristics that are necessary to increase the likelihood for successful ASP EOR applications.

EOR Target

The Bridgeport B sandstones in Section 32 are being targeted because these reservoirs are more compartmentalized than the thick channel fill sandstones in Section 5. These compartmentalized reservoirs are being used in an early phase assessment of ASP flood design and development in a confined area that results in the most effective flood recovery. The success from these Rex Energy-confined reservoir flood designs will be implemented in larger-scale floods, such as the 350-acre Delta region in the southern half of Section 32.

After developing the geological model, a geocellular model was constructed using the geological data and reservoir geometries as a foundation. This is used to confirm the geologic reservoir model and is required for effective reservoir simulation modeling. The 3-D modeling images are also a valuable visualization tool for evaluating reservoir characteristics such as compartmentalization, porosity, permeability and residual oil saturation. A comprehensive geologic reservoir characterization assessment is essential to develop an effective reservoir simulation model.

A simulation model that most precisely portrays the reservoir will increase accuracy of pore volume calculations used for chemical input estimations and oil recovery projections, and can be used for effective flood design. The finalized geocellular model, located in the northeast quarter of Section 32 and containing permeability, porosity and oil saturation, was then transferred to Rex Energy for use in simulation modeling. The results of the simulation will guide future development of the field for ASP purposes.

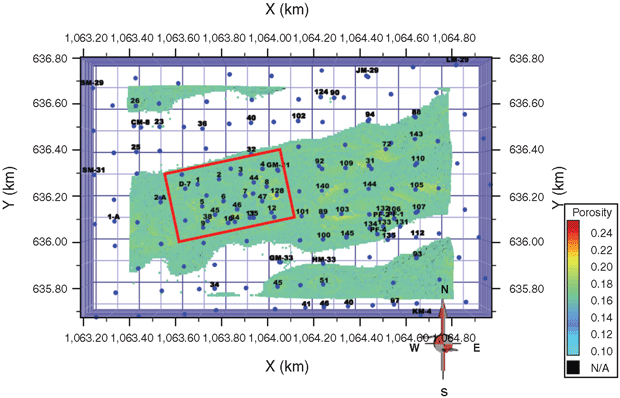

Figure 6 is a plan view of the Bridgeport B model, showing the outline of the reservoir. The model is 200 acres located in the northeast portion of Section 32 T4N R12W. This porosity model that displays an area where porosity is ≥16 percent. The red box outlines the location of Rex Energy’s ongoing Middagh ASP flood. Locations of older wells with SP data used to develop the model are shown as blue lines and dots, and modern porosity logs are labeled with black numbers.

Field Results

Rex Energy is reporting a positive response on its Middagh ASP pilot project in the Pennsylvanian Bridgeport B reservoir. Oil response in the 15-acre flood has continued to show an increase in the average oil cut from 1 to 12 percent. Total pattern oil production increased from 16 barrels a day to stabilize within a range of 65-75 bbl/d in the last three months of 2011. Peak oil production rose to 100-plus bbl/d, with some individual wells in the pilot showing oil cuts greater than 20 percent.

A second 58-acre pilot (Perkins-Smith) adjacent to and likely in communication with the Middagh pilot has been initiated. Preliminary brine injection is in progress with plans to initiate ASP injection by mid-2012. The response is expected by mid-2013 with peak recovery anticipated by late 2013. Rex Energy is projecting full-scale expansion, with the next step of development being a 351-acre project scheduled to begin in mid-2013. Preliminary development has been initiated in this Delta Unit area located in the southern half of section 32 T4N R12W.

Reservoir characterization has a critical role in developing a complex chemical EOR process such as ASP, especially in highly compartmentalized reservoirs that extend laterally from several acres to tens of acres in size. A synergistic approach between reservoir characterization and formation evaluation, coupled with reservoir modeling and simulation, reservoir management, well management and corresponding surface facilities, is the only approach to assure success in chemical flooding involving a high degree of technology such as ASP.

SINISHA “JAY” JIKICH is a project manager at the National Energy Technology Laboratory in Morgantown, W.V., where he manages EOR-focused projects. He is also an adjunct faculty in the chemical and petroleum engineering department at the University of Pittsburgh. Jikich has 30 years of experience in EOR, geological sequestration, reservoir characterization and simulation, and is the recipient of two Fulbright grants to lecture in the petroleum engineering departments in Hungary and Serbia. He holds an M.S. in polymer physics from the University of Bucharest and an M.S. and Ph.D. in petroleum engineering from the University of Wyoming.

JOHN GRUBE has 35 years of experience in petroleum geology research, and exploration and development, including 13 years serving in the industry in Denver and 22 years at the Illinois State Geological Survey, specializing in stratigraphy of cratonic basins, depositional environments, lithofacies modeling, play analyses, core, sample and outcrop analyses, field studies, reservoir geometry and heterogeneity, and enhanced oil recovery. Grube holds a M.Sc. in geology from the Colorado School of Mines.

BEVERLY SEYLER has 30 years of experience in petroleum geology research, reservoir characterization and depositional environments. She was head of the oil and gas section at the Illinois State Geological Survey for 12 years, retiring in 2010. Specialties include depositional environments, sedimentology, lithofacies modeling, petrography, field studies, and Paleozoic stratigraphy of the Illinois Basin. Seyler holds an M.S. in geology and a M.A. in geography from the State University of New York-Fredonia and the State University of New York-Buffalo.

NATHAN WEBB is a geologic specialist at the Illinois State Geological Survey. He has been with the survey since completing a master’s in glacial geology and geomorphology at the University of Illinois at Urbana-Champaign in 2009. Webb’s work involves stratigraphic and sedimentological studies of petroleum reservoirs in the Illinois Basin.

JAMES DAMICO has been an assistant geologist at the Illinois State Geological Survey since 2006. His focus is on using geostatistical methods to characterize heterogeneity in reservoirs and building 3-D computer simulations of reservoir architecture using stochastic methods. Damico holds a B.S. in earth sciences from Purdue University and an M.S. in geology from Wright State University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.