Software Solutions Harness Power Of AI In Array Of Applications

By Danny Boyd

Oil and gas fields are proving fertile ground for the proliferation of artificial intelligence.

AI-based solutions are being deployed in every imaginable manner in both upstream and midstream operations as innovators in digital, data science, and software technologies answer the call from operators of all sizes to harness the might of AI to drive optimization and efficiency gains.

Among them is Actenum, a Canada-based company that continues to advance its AI-infused software platform to schedule drilling, completion, tie-ins and workovers, says Vice President of Business Development Owen Plowman.

The company’s Decision Support and Optimization (DSO) software can compute numerous strategies to guide drilling and completion programs while satisfying objectives such as maximizing production or staying within budget, Plowman says. It can quickly adjust a schedule to reflect drilling delays caused by stuck pipe, weather, power outages, and a host of other issues, and can create and evaluate numerous alternative scenarios to compare schedule options and how well each can achieve pre-determined key performance indicator (KPI) objectives.

“We use artificial intelligence to optimize the schedule against multiple objectives, which sometimes conflict with one another,” Plowman explains. “Users can try to get as much production as possible, but of course, they also have a budget ceiling that impacts how much money they can spend. Our tool does trade-off analysis automatically.”

Plowman reports that Actenum is pushing the innovation envelope for generative AI (GAI) with developers working on an add-on to help users get answers to more complex questions regarding various competing development scenarios. Rollout is expected in four to six months, he adds.

Two-Expert Approach

Actenum has a design philosophy called the “two-expert approach,” according to Plowman. Using this tactic, the computer does the heavy lifting in scheduling drilling and incorporating corresponding changes in completions and tie-ins. However, the approach factors in human knowledge and expertise to get the best results.

Actenum’s Decision Support and Optimization (DSO) software can compute numerous strategies to guide drilling and completion programs while satisfying objectives such as maximizing production or staying within budgets. It can quickly adjust scheduling to reflect drilling delays and create and evaluate numerous alternative scenarios to compare schedule options and how well each can achieve pre-determined KPI objectives.

For example, in a two-rig drilling program, the computer may consider that it has two identical resources to use when considering rig schedules. On the other hand, a seasoned professional may know that one rig usually bests the other in performance and can change the schedule to utilize the faster rig on a certain job as needed, Plowman says.

The approach and deployments have reaped handsome results for users. During the pandemic, a major oil company was able to run multiple scenarios quickly on how to ramp down and then ramp back up operations. Plowman reports that the effort liberated about $100 million in free cash flow.

The user, who was previously scheduling using Microsoft Excel, saved 1,000 hours of time per year after switching to the AI software and twice won an information technology award that recognizes innovations among both organizations and individual IT professionals.

For another operator, the software allowed for modeling of various potential scenarios in days instead of weeks and improved resource allocation and minimized nonproductive time, Plowman shares.

Typically, one power scheduler can make information available to 100-200 colleagues using Actenum’s DSO/CX, which incorporates schedule visualization and reporting capabilities, including GIS mapping, so that any authorized user can view an optimized schedule on the web.

Reports and software-generated updates to drilling programs can be reviewed by affected employees and managers using a desktop or cellphone with Power BI or Spotfire applications, he notes.

Fracturing Optimization

Advancements in machine learning, image recognition and large language model (LLM) capabilities are supporting the work of Corva as it broadens the capacity of its AI-powered platform to speed up and improve drilling and completions, says Ryan Dawson, founder and chief executive officer.

The company has recently deployed a new predictive fracturing optimization platform on about 250 wells with capabilities to design completions and treatments to optimize performance and efficiencies.

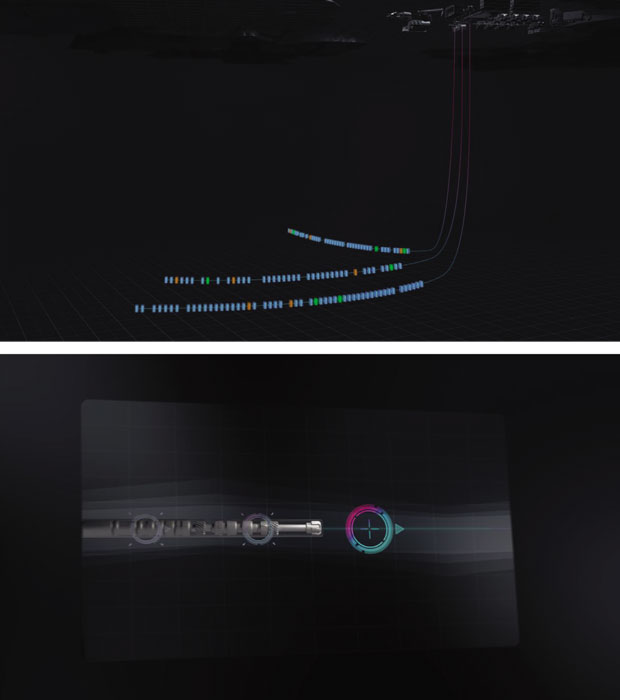

Advancements in machine learning, image recognition and large language model capabilities are enabling Corva to broaden the capacity of its AI-powered platform to speed up and improve both completions and drilling. The company has deployed its new predictive fracturing optimization platform (top) on about 250 wells with capabilities to design completions and treatments to optimize performance and efficiencies. The predictive drilling optimization platform (bottom) has been deployed on about 200 wells, increasing drilling efficiency by 20% on average.

Predictive frac can ingest all data from geophysical and drilling operations as it identifies recommendations for completion designs. Before operations begin, the software can predict with 90% accuracy which stages are going to be problematic so teams can pay particular attention to them and adjust operations upon seeing a divergence in pressure and other changes, Dawson relates.

Corva is developing a capability to adjust pumping pressure, proppant and fluid, including sensing changes in viscosity to identify necessary adjustments in friction reducer.

With the speed of cloud-based computing improving by sub-one second latency on Starlink, the solutions can be calculated and offered within a few seconds from data extracted at a rig or completion site, uploaded to the cloud, calculated with a cloud-based algorithm, and the solution transmitted back down to the job site, Dawson says.

While development and improvement can take time, its AI systems are increasingly capable of directing autonomous control of wellsite equipment for continuous optimization, he shares.

Predictive Drilling

Additionally, with the incorporation of LLMs, users can type English queries into a sidebar to notify Corva’s predictive drilling software to identify, for example, a specific range of sensor traces to assess potential complications and pre-identify solutions. The software can predict stuck pipe and other drilling complications and includes advanced visualization.

“Our software can predict drilling speed, and on average we have seen a 20% increase in drilling efficiency over about 200 wells that our software has been deployed on. We did that simply by boosting rate of penetration (ROP),” Dawson remarks. “It is still being proved out, but reducing problems and the amount of bit runs is something we are seeing come out of this. Independent of the 20% improvement in ROP, drilling can be adjusted to be done in one run. Beyond that, as people move a lot of their drilling operations into remote operating centers, it is a huge benefit, too.”

Preset drilling parameters for weight on bit or ROP, and thousands of changes in parameters during a well operation, have been simplified to five or six settings, freeing up personnel to focus on enhancing safety and preparing for the next operation, he says.

A Permian operator using predictive drilling automated parameters of weight on bit, rpm, and differential pressure to achieve a 26% increase in on-bottom rotary ROP and a 30% reduction in average bit trips compared to offset pads. Cost savings per pad amounted to $270,000.

For an Eagle Ford operator, the software trimmed half a day off drilling times compared to the fastest offset well. The last lateral drilled in the program was done 1.5 days faster than offset wells. Altogether, the operator saved $315,000 per pad, realized a 30% improvement in capital efficiency, and achieved a 91% utilization rate with predictive drilling.

Through cellular or Wi-Fi connectivity, the company provides data availability and analytics to help clients make decisions in real time, he goes on. The goal has always been to simplify operations and allow control from remote centers, or even by phone in the future, Dawson says.

Seismic Interpretation

From the earliest days of incorporating machine learning and AI techniques in oil and gas, it became increasingly apparent that a prime application area was in processing and analyzing 3-D seismic datasets. But roll the calendar back 17 years—a veritable eternity in terms of digital technology—and one company already had that figured out. Since its founding in 2008, Geophysical Insights has been all about incorporating advanced machine learning algorithms and logic in its flagship Paradise® seismic interpretation software.

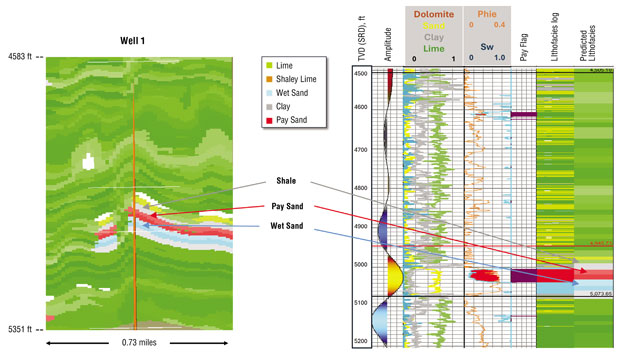

One of Geophysical Insights’ newest AI and machine learning-enabled advancements is lithofacies prediction. With these technologies, the interpretation time needed for fault generation and lithofacies prediction has been reduced by 90% compared to traditional geostatistical seismic inversion.

Today, Geophysical Insights’ suite of AI-powered applications is enabling operators to access higher-resolution reservoir interpretations, detect and analyze faults, and better classify seismic facies to enhance assessments of rock quality, optimize wellbore placement, and improve completions designs.

Tools like deep learning fault detection and machine learning stratigraphic analysis have been available for several years, says Hal Green, director of marketing and business development. However, the technologies are just now being adopted into standard geoscience workflows, despite published case studies worldwide on their effectiveness and efficiency.

The company continues to advance its Paradise software suite, which provides several AI-enabled geoscience workflows. The technology speeds the time-consuming process of fault detection, stratigraphic analysis, lithofacies prediction, and other geoscience workflows. Working at the seismic sample interval, their tools facilitate reservoir modeling by calculating the probability of designated lithologies.

“More recently, Geophysical Insights has developed a breakthrough in machine learning lithofacies prediction that is accelerating reservoir characterization dramatically, by as much as 10 times,” Green reports.

With a focus on continuous improvement, the company currently is working with one large unconventional operator to identify chert using machine learning lithofacies prediction technology that shows promise, he says. In another case, the company is training a customer in their software to identify lithofacies in the Powder River Basin. Geophysical Insights published a case study on the Niobrara formation in 2023 that demonstrated the effectiveness of the technology in an unconventional setting.

Slashing Cycle Times

Green points out that there is a substantial and growing body of evidence that seismic interpretation times are being dramatically compressed with AI technologies. Not long ago, 3-D seismic interpretation turnaround times were a waiting game affected to varying degrees by limitations in computing hardware and data management capabilities. With the assistance of AI tools, seismic interpretation cycle times—and the corresponding waits to arrive at an informed decision point—are being dramatically compressed.

“We can obtain fault detection results in a few hours to a few days, which used to take several weeks,” he comments. Within a 30-day project window, machine learning technology can be used to identify and quantify—assign probabilities—on the location of specified lithofacies. Obtaining the same results with traditional geostatistical seismic inversion would take months. Green reveals that compared to traditional interpretation time, fault generation and lithofacies prediction have been accelerated by 90%.

Rapid progress of computing power enables the company to analyze large, complex, high-resolution surveys much faster and more efficiently, but other factors impact the time for reservoir characterization.

“As the history of our industry and others demonstrates, geoscience and engineering software applications often precede the capabilities of the computing hardware and storage systems,” Green says. “This is precisely what we see today. Oil and gas companies want to apply AI to ever-larger surveys, but the bottleneck is typically the available computing facilities.”

To overcome restraints, commercial cloud services like Google, AWS, and Azure enable the deployment of applications with the optimal hardware, storage capacity, and scale needed.

With younger users more versed in AI and large language models like ChatGPT, Green predicts that any reluctance to embrace these technologies will quickly fall to the wayside as E&P managers begin to see the undisputed value in leveraging AI in appropriate workflows.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.