Unconventional Gas, Ultradeepwater Technology Focus Of R&D Programs

By Kent Perry

SUGAR LAND, TX.–In January 2007, the U.S. Department of Energy’s National Energy Technology Laboratory awarded a contract to the Research Partnership to Secure Energy for America (RPSEA) to manage the “ultradeepwater and unconventional natural gas and other petroleum resources

research and development program” pursuant to the Energy Policy Act (EPAct) of 2005. RPSEA is a nonprofit corporation composed of a consortium of U.S.-related entities dedicated to increasing America’s supply of energy. Participation in RPSEA is open to all organizations resident or incorporated within North America that are actively engaged in the energy industry or energy-related research. With more than 100 members, RPSEA membership represents a broad cross section of energy stakeholder viewpoints and talent.

The EPAct legislation includes three program elements:

- Ultradeepwater architecture and technology;

- Unconventional natural gas and other petroleum resource E&P; and

- Technology challenges of small producers.

This article describes the unconventional natural gas and other petroleum resources research and development program, and the portfolio of research projects that have been selected as part of the initial R&D program.

Unconventional natural gas resources are best described as those gas accumulations that cannot be identified, characterized and commercially produced by common exploration and production technologies. For example, it is almost impossible to identify tight lenticular gas-bearing sand bodies by state-of-the-art seismic imaging, or determine their flow properties from petrophysical well surveys. Furthermore, because of their very low permeability, establishing gas flow at a reasonable commercial rate requires production stimulation operations. These features attach a high risk factor to virtually all unconventional gas exploration and development projects that can avert the industry from these resources.

Unconventional natural gas resources typically are located in heterogeneous, extremely complex, and often poorly understood geologic systems. The challenge is to characterize these resources in view of their producibility and identify technology needs for their commercial production.

Unconventional Gas R&D

The goal of the unconventional resources R&D program is to increase the supply of domestic natural gas and other petroleum resources through the development of technologies that reduce the cost and increase the efficiency of exploration and production of these resources, while improving safety and minimizing environmental impact.

In order to assure a significant impact with limited funding, the initial program is focusing on a limited number of potential resources.

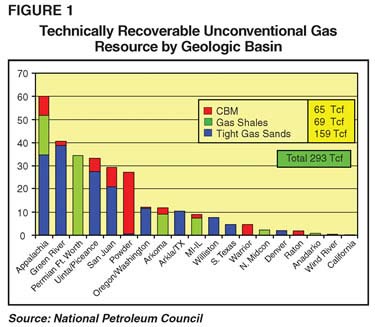

The contribution of natural gas to the nation’s energy supply from three specific unconventional resources—gas shales, coal seams and tight sands—has grown significantly during the past 20 years. These resources have been identified by the Energy Information Administration and others as critical supply sources for the next two decades. According to the latest estimate by the National Petroleum Council (2003), the volume of technically recoverable gas from these three resources in the lower-48 states is in excess of 293 trillion cubic feet (Figure 1).

More recent studies, especially in the area of gas shale resources, have indicated that these numbers may be very conservative. New shale plays such as the Marcellus, Conasauga, Floyd and others are putting up some significant numbers for gas in place and technically recoverable gas. A new study to update all of the unconventional gas resource estimates is overdue.

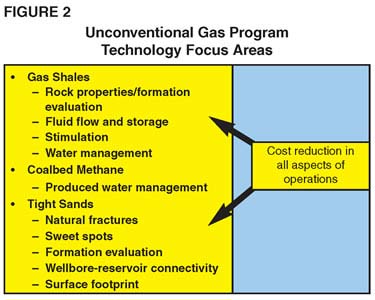

Specific technology focus areas associated with the targeted resources are shown in Figure 2. Advances in these areas will lead to wells that are better located and connected to the reservoir, resulting in fewer overall wells required to produce a given reservoir. Drilling fewer wells not only improves the economics of unconventional gas development, but directly reduces the environmental impact of unconventional gas operations.

Field-Based Approach

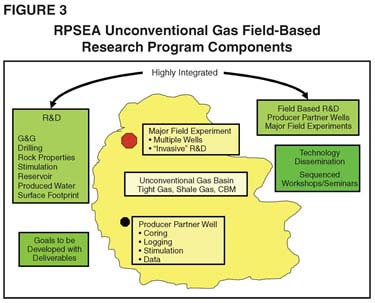

The unconventional gas R&D program will include a strong field-based research component. Actual field test sites will serve as the research laboratory and will bring program producer involvement to all stages of the research. It is through the field research that technology dissemination also begins to take root.

The field program (illustrated in Figure 3) utilizes two primary research vehicles. The first is producer partner wells (PPW). These are wells currently being drilled and completed in an unconventional gas area by a producing company. RPSEA will “piggyback” research experiments such as special coring, well logging or testing on top of the normal operations to gather needed research data for the R&D experiments. This type of well provides highly leveraged information valuable to both the producer partner and the research program.

The second research vehicle is major field experimentation (MFE). At some point within the research program, the type of data required often becomes “invasive” to the commercial goals of a producer partner well. As these needs accumulate, they form the basis for a research experiment that includes dedicated wells for the research program. The field-based research program anticipates this need and includes plans for dedicated research sites in yet-to-be selected unconventional gas plays to provide detailed experimental data and a controlled testing platform.

The field-based program will serve to assure integration of research projects into a focused program. All researchers involved in the program will be included in the design of field operations and will utilize the data within their research efforts. Verification of new procedures and techniques will begin to take place in the field, providing a strong springboard for technology transfer.

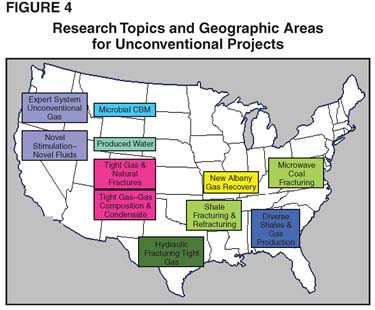

Nineteen proposals have been selected for negotiations leading to an award under the unconventional resources program focused on increasing the supply of domestic natural gas and other petroleum resources.

The unconventional resources program is designed to bring the resources of America’s leading universities, research institutions and technology innovators to bear on the development of gas shales, tight gas sands and coalbed methane resources by reducing costs, increasing efficiency, improving safety and minimizing environmental impacts (Figure 4).

While awards under the RPSEA unconventional resources program are open to any U.S.-based organization, most projects involve a team consisting of researchers along with producers or service companies that are in a position to evaluate and apply new technology. Each proposal must provide a minimum of 20 percent cost-sharing for R&D projects, and 50 percent for field demonstration projects.

Initial Research Portfolio

The selected research projects for RPSEA’s unconventional resources program are:

- A self-teaching expert system for analyzing, designing and predicting gas production from shales (Lawrence Berkeley National Laboratory is the project leader, with Texas A&M University, the University of Houston, Southwestern Energy and Anadarko Petroleum Corporation participating);

- Advanced hydraulic fracturing technology for unconventional tight gas reservoirs (Texas A&M University is the project leader, with Carbo Ceramics, Schlumberger, Halliburton Energy Services and BJ Services participating);

- An integrated framework for treatment and managing produced water (Colorado School of Mines is project leader, with Kennedy/Jenks Consultants, Argonne National Laboratory, Stratus Consulting, Eltron Research & Development, Chevron, Pioneer Natural Gas, Marathon, Triangle Petroleum, Anadarko, Awwa Research Foundation, Stewart Environmental, Southern Nevada Water Authority, Veolia Water, Hydration Technology and Petroglyph Operating Co. participating);

- Applying natural gas composition to modeling communication within and filling of large tight gas sand reservoirs in the Rocky Mountains (Colorado School of Mines is project leader, with the U.S. Geological Survey, University of Oklahoma, University of Manchester, Fluid Inclusion Technology, Permedia Research Group, Williams Exploration & Production Co., ConocoPhillips, ExxonMobil, Newfield Exploration, BP, Anadarko, EnCana Oil & Gas and Bill Barrett Corporation participating);

- Comprehensive investigation of the biogeochemical factors enhancing microbially generated methane in coalbeds (Colorado School of Mines is project leader, with the University of Wyoming, USGS, Pioneer Natural Resources, Pinnacle Gas Resources, Coleman Oil & Gas, and Ciris Energy participating);

- Enhancing Appalachian coalbed methane extraction by microwave-induced fractures (Pennsylvania State University is project leader, with Nottingham University participating);

- Gas condensate productivity in tight gas sands (Stanford University is project leader);

- Gas production forecasting from tight gas reservoirs: Integrating natural fracture networks and hydraulic fractures (University of Utah is project leader, with the Utah Geological Survey, Golder Associates, Utah State University, and HCItasca participating);

- Geological foundation for production of natural gas from diverse shale formations (the Geological Survey of Alabama is project leader);

- Improved reservoir access through refracture treatments in tight gas sands and gas shales (University of Texas at Austin is project leader, with Noble Energy, BJ Services, Anadarko, Jones Energy and Pinnacle Technologies participating);

- Improved fracturing for gas shales (University of Houston is project leader, with Daneshy Consultants and BJ Services participating);

- New Albany Shale gas (The Gas Technology Institute is project leader, with Amherst College, University of Massachusetts, ResTech, Texas A&M, Pinnacle Technologies, West Virginia University, Texas Bureau of Economic Geology, Aurora Oil & Gas, CNX Gas, Diversified Operating Corporation, Noble Energy, BreitBurn Energy and Trendwell Energy Corporation participating);

- Novel concepts for unconventional gas development in shales, tight sands and coalbeds (Carter Technology is project leader, with University of Oklahoma, University of Houston and M-I LLC participating);

- Novel fluids for gas productivity enhancement in tight formations (University of Tulsa is project leader, with Williams Exploration & Production Co. participating);

- Optimizing infill well locations in the Wamsutter Field (University of Tulsa is project leader, with Texas A&M and Devon Energy participating);

- Optimizing development strategies to increase reserves in unconventional gas reservoirs (Texas A&M is project leader, with Unconventional Gas Resources Canada Operating Inc. and Pioneer Natural Resources Co. participating);

- Paleozoic shale gas resources of the Colorado Plateau and Eastern Great Basin, Utah: Multiple frontier exploration Opportunities (Utah Geological Survey is project leader, with Bereskin & Associates, GeoX Consulting and Halliburton Energy Services participating);

- Petrophysical studies of unconventional gas reservoirs using high-resolution rock imaging (Lawrence Berkeley National Laboratory is project leader, with Schlumberger, Chevron and BP participating);

- Reservoir connectivity and stimulated gas flow in tight sands (Colorado School of Mines is project leader, with University of Colorado, Mesa State University, iReservoir, Bill Barrett Corporation, Noble Energy, Whiting Petroleum Corporation and ConocoPhillips participating).

Funding for the projects is provided through the ultradeepwater and unconventional natural gas and other petroleum resources R&D program, authorized by EPAct with funding from lease bonus and royalties paid by the industry to produce oil and gas on federal lands for the purpose of maximizing the value of natural gas and other petroleum resources of the United States, by increasing the supply of such resources, through reducing the cost and increasing the efficiency of exploration for and production of such resources, while improving safety and minimizing environment impacts.

RPSEA is under contract with the NETL to administer the program. RPSEA is a 501(c)3 not-for-profit consortium with more than 130 members, including 25 of the nation’s premier research universities, five national laboratories, other major research institutions, large and small energy producers, and energy consumers. The mission of RPSEA is to provide a stewardship role in ensuring the focused research, development and deployment of safe and environmentally responsible technology that can effectively deliver hydrocarbons from domestic resources to the citizens of the United States.

Editor’s Note: Additional information on this and other programs funded under Section 999 of EPAct 2005 can be found at both RPSEA’s Web site and the NETL’s Web site.

KENT PERRY is team leader for unconventional onshore resources at the Sugar Land, Tx.-based Research Partnership to Secure Energy for America. He has responsibility for planning and managing a research program that has the overall objective of developing new technology for enhanced recovery of natural gas in the lower-48. With 30 years of natural gas engineering and production responsibilities, Perry previously served at Northern Illinois Gas Co., Kansas-Nebraska Natural Gas Co., and Michigan Energy Resources Co. He is a past Society of Petroleum Engineers distinguished lecturer, and has participated in National Petroleum Council studies on natural gas potential in the United States. Perry holds a B.S. in petroleum engineering from the Colorado School of Mines.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.