STACK And SCOOP Push Mid-Continent Energy To New Heights

By Al Pickett, Special Correspondent

At 40,000 feet thick in its deepest portion, the Anadarko Basin in western Oklahoma presents one of the premier shale targets in North America.

Newfield Exploration Co. opened the STACK (Sooner Trend Anadarko Canadian Kingfisher) play in 2013, shortly after Continental Resources Inc. announced its SCOOP (South Central Oklahoma Oil Province) discovery well in October 2012. Those two discoveries led to horizontal drilling and remarkable growth in Oklahoma oil production and reserves.

In fact, the U.S. Energy Information Administration estimates Oklahoma’s recoverable resource base had grown to 1.917 billion barrels by year-end 2017, more than double what it was only five years earlier, prior to the discovery of SCOOP and STACK.

Now, an acquisition that brings with it a new completion strategy for the STACK and an aggressive new project in the SCOOP appears certain to make those numbers increase even more. Encana Corporation finalized its acquisition of Newfield in February. Steve Campbell, who previously served as senior vice president of Newfield, has changed companies, but not jobs, taking over as senior vice president of investor relations and communications for Encana.

“The company got a lot bigger,” he remarks. “We are close to being a 600,000 barrel-a-day company. We are by far the largest oil producer in Oklahoma.” The acquisition of Newfield means Encana now has 365,000 acres in the Anadarko Basin, about 265,000 of which are in the STACK and another 90,000 acres are in the SCOOP.

Newfield’s average production during fourth quarter 2018 was more than 200,000 barrels of oil equivalent a day, including more than 125,000 bbl/d of liquids. On a pro forma basis, Encana’s and Newfield’s combined 2018 production would have averaged more than 555,000 boe/d, including approximately 290,000 bbl/d of liquids.

Cube Development

“The rationale for the acquisition was to create scale across multiple basins and to be able to leverage our vendors and operations to improve returns,” explains Campbell. “Rocks don’t know state or country boundaries, and everything is replicable from one basin to another. Encana is applying what it learned in the Permian Basin to the STACK.”

He says Newfield’s wells previously cost about $7.9 million each, but Encana has set a target of reducing that by more than $1.0 million a well, which Campbell says he is confident will be attained this year.

From using locally-mined and self-sourced sand, which lowers transportation costs, to a change in the workflow at the job site, and lowering cycle and drilling times, he says, Encana has put its focus on reducing the time between first investment and first return.

Encana is cutting back the number of rigs it is operating in the STACK, but because of the improvement in cycle time, it expects to complete nearly the same number of wells this year, Campbell says. It plans to go from the 11 rigs Newfield was running to four rigs by May, he says, but still will put about 100 wells on line in 2019. He adds that the company will go from four completion spreads to running two continuously.

He reports Encana is bringing cube drilling, which it has employed in the Permian and Montney basins, to the STACK, which is a new practice for Oklahoma. Encana is drilling 10,000-foot superextended laterals, similar to what Newfield was drilling. But instead of drilling wells in a row, it is drilling six-eight wells a section in a cube.

Following its acquisition of Newfield Exploration’s position, Encana Corporation is bringing cube drilling, which it has employed in the Permian and Montney basins, to Oklahoma’s STACK play. Cube drilling entails drilling one or two cubes, then returning in 12-24 months to optimize completions based on what the company has learned, explains Senior Vice President of Investor Relations and Communication Steve Campbell.

“Cubes and row drilling are distinctly different,” Campbell emphasizes. “With two-mile laterals, you could have six miles of activity. With cube drilling, you drill one or two cubes and then come back in 12-24 months. By doing that, we are reducing cycle times from 180 days or more to 90. We are producing revenue more quickly and are gathering geologic data at the same time. When we come back, we have the ability to quickly modify and optimize our results based on the knowledge we have gathered from our earlier program. If we get something wrong with row drilling, we do not have the same ability to change.”

He says Encana is drilling six Meramec wells a section. If it drills eight wells in a section, the other two likely are Woodford. There is also the potential for production from the Osage formation in its acreage, he adds.

Encana’s 2019 program is “very STACK focused” in Kingfisher and Canadian counties, according to Campbell. He says the company will have only a limited program in the SCOOP this year.

“The first half of the year, we will be focused on well cost reduction,” Campbell emphasizes. “If we can reduce well costs by $1 million, the STACK will be able to compete with any play in the country. The second half of the year we will focus on improved production from our cube drilling.”

Encana completed its first STACK cube in April.

Its full-year, pro forma capital budget for 2019 is $2.7 billion-$2.9 billion, which includes approximately $200 million associated with Newfield operations from Jan. 1 through closing the transaction on Feb. 13. Campbell reports that more than 75% of Encana’s capital investments this year will be allocated to its three core liquids plays: the Permian, Anadarko and Montney.

Full Development Phase

Clint Calhoun, vice president of resource development for Oklahoma City-based Chaparral Energy, says his company has moved from the delineation phase to multiwell development in the STACK.

Chaparral has approximately 131,000 net acres in the STACK that Calhoun says provide access to several formations, most notably the Meramec, Osage, and Woodford, allowing the company to drill multiple zones from a single pad. It operated four rigs through the first quarter, but dropped to three rigs in April, where Calhoun says Chaparral plans to stay for the remainder of the year.

What makes the STACK attractive to Chaparral?

Chaparral Energy, which is drilling six-eight Meramec and Osage wells per section in the STACK, utilizes an earth model derived from 3-D seismic to help pick well locations, target intervals and well density, according to Vice President of Resource Development Clint Calhoun. Fractures are designed to enhance near-wellbore stimulated reservoir volume and to manage parent well communication risk.

“Repeatability,” Calhoun replies. “With multiple zones, lower drilling costs and strong rates of return, it is very attractive. Of course, it is close to Cushing, Ok., too, which helps to provide a low break-even cost. The geology is favorable in the STACK with a world-class source rock in the Woodford, multiple reservoir development opportunities, and more than 700 feet of saturated hydrocarbon column.”

Chaparral increased its STACK production to 16,600 boe/d during fourth quarter 2018, up 6% compared with the previous quarter. Full-year STACK production grew by 52% to 14,400 bbl/d last year compared with 2017. Its 2018 total company production was 61% liquids (36% oil and 25% natural gas liquids) and 39% natural gas.

Calhoun says part of the company’s strategy for 2019 is to accelerate development in Canadian County, Ok, and to define optimal well spacing across de-risked acreage.

“We are looking to optimize well spacing in Canadian and Kingfisher counties as we continue to conduct spacing tests in these key areas,” he states. “Approximately 60% of our 2019 drilling and completion capital will go to our oil-rich Canadian County position, while 20% will go toward continued development in Kingfisher County and around 20% to Garfield County.”

As Chaparral works on optimizing its well spacing, Calhoun says, there are several factors to consider. “Our development design strives for the optimal balance of high rates of return and net present value,” he emphasizes. “That is something Chaparral really focuses on. We utilize an earth model derived from 3-D seismic to help pick our well location, target interval and well density. We design our fractures for enhanced near-wellbore stimulated reservoir volume and manage parent well communication risk. We are continuously evaluating and applying what we learn from one project to the next to ensure we are getting the absolute most out of every dollar we invest in our operations.”

Calhoun says Chaparral uses a systematic approach to spacing development. “Our initial indications point to six-eight Meramec and Osage wells per section,” he states.

As of year-end 2018, he says, the company believed it had effectively de-risked more than 80% of its Canadian County position and more than 50% of its Garfield County leasehold.

Chaparral Energy grew its STACK production to 16,600 barrels of oil equivalent a day in fourth quarter 2018, up 6% from the third quarter. Full-year STACK production grew by 52% compared with 2017, to 14,400 boe/d. According to Vice President of Resource Development Clint Calhoun, Chaparral’s STACK type curves range from 584,000 to 1.46 million boe (54-72% %liquids).

He adds that Chaparral brought 44 gross operated Meramec and Osage wells on line in 2018. “Those wells outperformed the company’s expectation with an average three-phase, 30-day initial production rate of 750 boe/d, of which 47% was oil and 26% was NGLs,” Calhoun reports.

While Chaparral’s 2018 wells averaged approximately 4,700 feet, it has drilled laterals as long as 7,500 feet in the STACK. Calhoun says the total vertical depth for Chaparral’s STACK wells varies from 7,000 to 10,000 feet.

He also points out that production rates vary by zone and by county. Chaparral’s STACK type curves range from 584,000 to 1.46 MMboe (54-72% liquids) with a rate of return ranging from 30% to more than 60%.

At present, Chaparral is drilling two-four wells per pad, Calhoun says, adding that the company has done a good job of lowering well costs.

“We look at every dollar we spend. In many cases, we use short-term contracts with our service providers, which allows us to be more flexible. We build our own locations, which saves some money,” he outlines. “It’s this laser focus that has allowed us to become one of the lowest-cost operators in the play. In fact, our cost per lateral foot is among the best in the industry at around $800 a foot.”

Project SpringBoard

A year ago, Continental Resources announced a massive undertaking in the SCOOP. Project SpringBoard is expected to add more than 16,500 barrels of daily oil production (an increase of more than 10%) to Continental’s overall production between third quarter 2018 and third quarter 2019.

In making the initial announcement in May 2018, Continental said it could drill up to 350 wells in a 73 square-mile area of South-Central Oklahoma. Project SpringBoard includes 47,000 gross (35,000 net) acres with an unrisked resource potential of more than 400 MMboe, according to a company news release. The company says it will operate SpringBoard with an average working interest of 75% in the project.

“SpringBoard marks the beginning of full-scale development of our SCOOP oil assets, following years of exploration, leasing and delineation drilling,” Vice President of Exploration Tony Barrett said in making the announcement. “These barrels represent some of the most profitable barrels within the company.”

The company provided a Project SpringBoard progress update in January, announcing that row one had been completed in the Springer formation with an average per well EUR of 1.3 MMboe.

Continental Resources’ Project SpringBoard in Oklahoma’s SCOOP play is expected to add more than 16,500 barrels a day of crude production to the company total by the third quarter. The project consists of 47,000 gross acres (35,000 net) in a 73-square-mile area of South-Central Oklahoma that have an unrisked resource potential of more than 55 million barrels of oil equivalent.

Continental had seven rigs drilling Springer wells in rows two and three with 16 wells waiting on completion and another five rigs drilling in the Woodford/Sycamore zones, where 17 wells were awaiting completion, the January report indicated. It also increased lateral lengths from 7,500 to 9,800 feet, the company said. A total of five rows will be drilled as it co-develops both reservoirs.

Continental says it plans to drill three-four Springer wells a unit, two-four Sycamore wells a unit and five-six Woodford wells at 11,000 feet deep. The Springer wells are producing 80-85% oil, while the Woodford/Sycamore wells are approximately 70% oil.

By year-end 2020, Continental says it expects to drill 31 operated units and up to 85 wells in the Springer formation. It also plans to drill 31 operated units and up to 250 wells (excluding parent wells) in the Woodford/Sycamore zone.

While well costs increased 5% by drilling the longer laterals in the Springer formation, the cost per lateral foot was reduced 20%, according to a company update. Per well EURs increased 8%, from 1.2 MMboe to 1.3 MMboe.

Continental claims it has achieved a 10% reduction in Springer completed well costs, lowering drilling costs by 18% and cycle times by 24%. It also says it is completing 45% more stages a day. The company says it is targeting an additional 6-8% reduction in Springer completed well costs this year, including a 15% reduction in both drilling costs and drilling cycle time. Completion costs, however, will remain flat, according to company projections, while proppant loads increase by 30%.

Overpressured Condensate Unit

While Project SpringBoard in the SCOOP is Continental’s primary focus this year, the company reports that its fourth-quarter STACK production also increased 12% over the third quarter and 31% over fourth quarter 2017, averaging 62,947 boe/d. Continental says it completed 19 gross (nine net) operated STACK wells in the fourth quarter with first production flowing at an average 24-hour rate of 3,645 boe/d per well.

Continental says it has completed an outstanding Meramec unit in the STACK’s overpressured condensate window. The three-well Boden unit flowed at a combined initial 24-hour rate of 14,071 boe/d, averaging 1,197 bbl oil and 20.961 MMcf/d of natural gas per well.

“Results from the Boden unit further validate Continental’s optimized density development and the high quality of the overpressured Meramec that underlies our acreage position in the STACK,” states company President Jack Stark.

Oil Growth Transformation

Devon Energy announced in February that it was separating its Canadian and Barnett Shale assets to complete its transformation to a high-return U.S. oil-growth business. The STACK play is a key component of that strategy.

Devon reported 296,000 boe/d fourth quarter production from its four top oil-producing basins: STACK, the Delaware in southeastern New Mexico, the Eagle Ford in South Texas and the Powder River in Wyoming. Eighty-four percent of the company’s fourth quarter revenue came from oil and liquids.

Devon says the STACK represents its largest producing asset, generating 126,000 boe/d (55% liquids) in the fourth quarter. That is 24% of the company’s portfolio.

“With our world-class U.S. oil resource plays rapidly building momentum and achieving operating scale, the final step in our multi-year transformation is an aggressive, transformational move that will accelerate value creation for our shareholders by further simplifying our resource-rich asset portfolio,” says Devon President and Chief Executive Officer Dave Hager.

He adds, “New Devon will emerge with a highly focused U.S. asset portfolio, and has the ability to substantially increase returns and profitability as we aggressively align our cost structure to expand margins with this top-tier oil business. The new Devon will be able to grow oil volumes at a mid-teens rate while generating free cash flow at pricing above $46 a barrel.”

Devon Energy says its STACK operations are focused on the oil-prone Meramec and the liquids-rich Cana-Woodford Shale. The company reports a 90% improvement in drilling rates at its Safari development in Kingfisher County, Ok., where infill wells have average 30-day initial daily production of 1,400 barrels of oil equivalent.

Oil-Prone STACK

Devon says it has a core acreage position of 280,000 net acres in the STACK, primarily in Oklahoma’s Canadian, Kingfisher and Blaine counties. Its position is contiguous and is located in the overpressured oil window, which it says is the economic heart of the play.

Its STACK operations are focused on the oil-prone Meramec and the liquids-rich Cana-Woodford Shale, the company adds, saying much of its emphasis is on optimizing infill spacing and accelerating efficiencies.

For example, in its Safari development in Kingfisher County, Devon reports a 90% improvement, from 625 feet drilled a day on the Safari parent well to 1,210 feet a day on infill wells. Infill drilling and completion costs were 30% below those of the parent well, the company adds.

It says the Safari design supports future infill drilling. Spaced at five wells a unit, Devon says Safari wells had average 30-day initial production of 1,400 boe/d.

The company reports a 9% increase in fourth quarter oil production over the third quarter, driven by infill development activity, and an 11% net production increase compared with fourth quarter 2017.

The highest fourth-quarter rates came from its Chipmunk (three wells) and Faith Marie (two wells) activity, which saw average 30-day IPs of 4,400 boe/d and 3,100 boe/d, respectively, Devon reveals. It says the Upper Meramec has been the best performing interval.

“2018 was a pivotal year for Devon as we took several significant steps toward achieving our long-term strategic goals,” Hager states in the company’s fourth-quarter earnings report. “Operationally, we successfully transitioned our franchise U.S. oil business into full-field development, which resulted in high-return, light-oil production advancing 20% in the fourth quarter.”

Hager says Devon’s 2019 strategic priorities include transitioning infill developments to four-six wells a unit and concentrating investment in the volatile oil window, primarily targeting the Upper Meramec interval.

The company adds that it plans to invest $400 million in the STACK this year, operating a four-rig program. Hager says Devon has significant growth inventory remaining with 130,000 net acres in the overpressured oil window as well as high-quality Woodford optionality.

Kansas Still Active

Although Kansas isn’t experiencing much of the horizontal drilling so prevalent in unconventional resource plays in Oklahoma and other U.S. basins, there is plenty of activity in the Sunflower State. Kenneth White, president of the Kansas Independent Oil & Gas Association, reports 35 rigs were running in the state in mid-April.

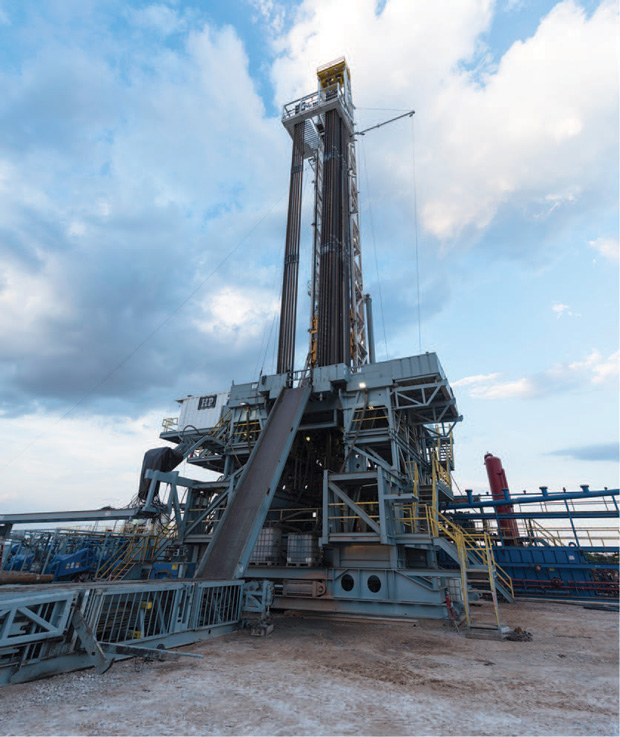

Wichita, Ks.-based White Exploration Inc. has drilled two wells this year and plans a couple more targeting the Morrow Sands in Stanton County, Ks., where this photo was taken, and the Mississippian in Barber and Pratt counties in South-Central Kansas.

“Most of the exploration is in Northwest Kansas and on the Central Kansas Uplift,” he reveals. “It is all oil at present. There is no gas exploration because of prices. Most of the wells in Kansas are vertical, with only a handful of horizontal wells.”

White, who is president of Wichita-based White Exploration Inc., says his company has drilled two wells this year and has a couple more planned. It is targeting the Morrow Sands in Stanton County in Southwest Kansas and the Mississippian in Barber and Pratt counties in South-Central Kansas. The Mississippian is 4,500 feet deep, while the Morrow is at 5,700 feet.

“The Mississippian wells in South-Central Kansas take a large fracture by our standards (about 420,000 gallons of freshwater and 200,000 pounds of sand) and cost about $600,000,” he details. “The Morrow wells in Southwest Kansas are deeper, but take a very small frac and cost about $550,000 each.”

A Diverse Portfolio

Palomino Petroleum in Newton, Ks., is one of the state’s most active operators with more than 150,000 acres leased across Northwest and West-Central Kansas, according to company President Klee Watchous. He says Palomino is targeting the Mississippian in Ness, Trego, Gove, Lane, Logan and Scott counties in Northwest Kansas and other formations such as the Arbuckle and Lansing in Barton and other counties in the west-central part of the state.

“We also are testing the Hunton, which lies below the Mississippian, in Harvey, Marion and Butler counties,” he relates. “We have a variety of locations and a diversity of areas and formations.”

One of Kansas’ most active operators, Palomino Petroleum in Newton, hopes to drill 12 wells a month in 2019. Most of those wells will target the Mississippian in Ness, Trego, Gove, Lane, Logan and Scott counties in Northwest Kansas as well as other formations such as the Arbuckle and Lansing in Barton and other counties in the west-central part of the state.

Watchous adds that Palomino has shot “a lot of seismic,” which he says helps determine where it will drill.

“Our goal is to drill 12 wells a month,” he continues. “I am surprised there is not more drilling in Kansas. I think people are concerned about the longevity of current prices. It is profitable where we work. Lifting costs are low and we don’t do a lot of fracture stimulation, so the total cost of drilling and putting a well on pump is only about $350,000.”

Although Palomino drills mostly vertical oil wells that typically have 40-60 bbl/d of initial production, Watchous says his company did drill a horizontal Mississippian well in Ness County two years ago.

“It has produced 91,447 barrels in less than two years and is averaging about 80 bbl/d,” he says.

“Most of our activity this year will be developmental. We will drill some undeveloped acreage, but much of our acreage is held by production and we want to drill that,” Watchous adds.

Good Place To Work

Don Williams, vice president of Shakespeare Oil Co. in Salem, Ill., calls Kansas a good state in which to drill and operate.

“Leasing, drilling and lifting costs all are reasonable,” attests Williams, whose company also operates in Montana, Illinois and Indiana. “The landowners are very receptive. The Kansas Corporation Commission is tremendous, providing a fast turnaround on anything we do. And the service companies are very professional and efficient.”

Shakespeare has been operating in Kansas since 2003 and has 120 wells in production, mostly in Logan and Scott counties. It drilled 11 vertical wells in 2018 and plans to drill about 20 this year, mostly in western Kansas. At present, Williams says, the company is targeting a number of formations, including the Pennsylvanian, Lansing, Kansas City, Marmaton, Cherokee and Morrow Sands.

Don Williams, vice president of Shakespeare Oil Co. in Salem, Il., calls Kansas a good state in which to drill and operate, pointing to reasonable leasing, drilling and lifting costs as well as a professional and efficient corporation commission. Shakespeare operates 120 wells in Kansas, including this one in the southwest portion of the state.

Most of the wells are around 4,700 feet deep and make less than 100 bbl/d. Williams says the cost to drill and complete Shakespeare’s wells in western Kansas is only about $400,000, if they need a tank battery.

“We can make money at $35-$40 a barrel,” he maintains. “There is a decent payout on investment.”

Shakespeare is actively exploring for and developing oil and gas, with most of its drilling locations selected from 3-D seismic. Williams says Shakespeare has 60,000 total acres leased in Kansas, most of which are held by production. r At 40,000 feet thick in its deepest portion, the Anadarko Basin in western Oklahoma presents one of the premier shale targets in North America.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.