Study Assesses Trends, Techniques To Mitigate FDIs In Bakken Infill Development

By Darren Schmidt, Kyoung Suk Min and Stephen Guillot

GRAND FORKS, N.D.—As in other unconventional plays, parent-child well interactions have a significant effect on the productivity of Bakken Shale wells. Development decisions continue to be driven largely by surface constraints, suggesting more work is needed to improve future child well performance and mitigate fracture-driven interactions (FDIs).

Operators have implemented various strategies as defensive techniques to mitigate parent-child well interactions, including refracturing, increased spacing and sacrificing stimulation energy into the nearest child well. Today’s most common mitigation techniques include fracturing the child well closest to the parent well first and increasing well spacing.

An Energy & Environmental Research Center study analyzed pad wells completed by multiple operators in the Williston Basin from 2017 to 2021, including 230 well pads and 371 parent wells. These pads were selected to exclude atypical developments. For instance, only drilling spacing units (DSUs) where child wells were drilled parallel to active parent wells were included.

The five-year period was selected because parent-child impacts had become apparent by 2017 and operators were more likely to implement countermeasures. Data was assembled to characterize the parent well, identify whether a discernible strategy had been implemented to counter the depletion effect, describe the strategy and identify any significant production increase in relation to the parent well.

Parent well location was identified as either near the edge of the pad or in the middle, since location can impact completion strategy. Other parent well characteristics that were identified included the number of parent wells within the unit and whether parent wells were restimulated, received some intervention such as fluid loading or had no intervention. Completion dates were examined to determine if a stimulation order was employed based on the position of the parent well (referred to as a “subsurface” decision), or if the stimulation order was simply a “surface” decision, such as completing the wells in sequence related to wellhead positioning.

In addition, strategies were inferred from the data and characterized as stimulating in order (such as an west-to-east or east-to-west pattern), stimulating the well nearest to the parent first, or no strategy was identifiable. Data was obtained on refractured wells and used to glean insights. Within the dataset, analytics were applied to characterize parent-child well relationships such as well spacing, stimulation size, potential reservoir depletion and parent-child formation sequence (Bakken-Bakken or Bakken-Three Forks).

Study Results

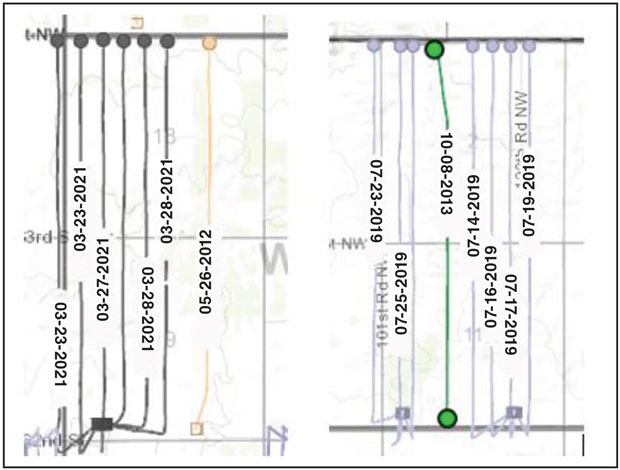

More than 2,500 wells were completed in the Williston Basin between 2017 and 2021. Parent wells were characterized within the 230-pad dataset. The two most dominant arrangements include a parent well located near the edge, or a parent well located in the middle of the DSU (Figure 1). Stimulation order can be established from completion dates and a strategy can be inferred as to whether the well nearest to the parent was stimulated first or last. Parent wells located in the middle of DSUs comprise 58% of the data compared with 42% of parent wells located near the edge.

Comparatively, 40% of the wells were stimulated beginning closest to the parent well, 33% were stimulated starting farthest from the parent well and 27% were identified as being a surface decision with stimulation order based on wellhead position. In addition, 82% of well completion decisions were attributed to surface decisions and only 18% to subsurface decisions. Although a substantial number of infill wells are stimulated closest to the parent well first, there are a limited number of cases that demonstrate a clear choice, and the stimulation order appears based on the DSU’s surface layout. In many cases, the development plan appears to be based on well pad location and efficient operational scheduling versus prioritizing subsurface attributes.

Production from parent wells was examined after child well development. In these cases, the parent well either was refractured, loaded with fluid or simply produced after shut in. If production was within 75% of the parent well’s initial production, the well was flagged as having a significant production response post-child-well development. Of 371 parent wells, 71 parent wells exhibited a significant production response. Although production response probably would be attributed to intervention such as refracturing, more than half the wells with significant production response simply were shut in and not restimulated or preloaded. The result is likely associated with nearby fracture stimulation of adjacent wells.

All the study’s refractured wells showed significant production response. Conversely, all the parent wells with limited production response were simultaneously identified as having no intervention. Therefore, on rare occasions, a parent well may have experienced a production increase from neighboring well stimulation. Sixty-seven DSUs specifically were identified as having at least one “sacrifice frac,” meaning the child well was closely spaced to the parent well and stimulated first to sacrifice the pumping energy to repressurize the parent well. Significant production response of the parent well was identified in 24 of these cases. The cases varied, including a parent well with a sacrificial frac to one side, a parent well with sacrificial fracs on both sides and refractured parent wells combined with sacrificial fracs.

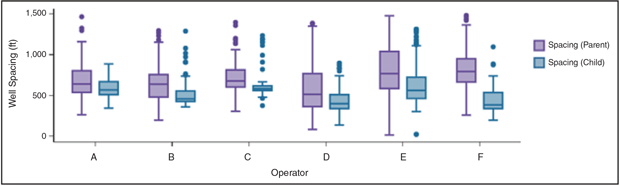

FIGURE 3

Distance for Parent versus Child Well from Subject Well (Subject Well is Closest Child to Parent Well)

Various operator strategies were reviewed over time to get a sense of how parent-child well decisions were being considered in North Dakota. A closer look at completion strategies is instructive as to the trends and commonality among operators. The dataset includes 224 spacing units that had active child drilling and completion programs between 2017 and 2021. Because well files with information regarding managed pressure operation on parent wells during offset frac activity were unavailable, this analysis was limited to observing refracturing of parent wells and sacrificial frac treatments of the child well nearest the parent.

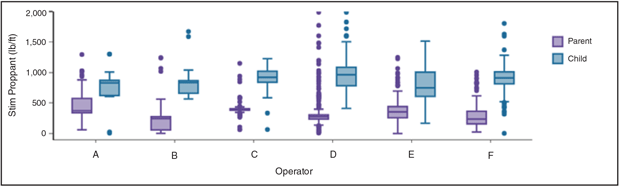

Data analytics also was applied to selected operators to explore child well strategies. It is expected that well spacing, stimulation intensity and depletion of the parent well with respect to the closest child well have a significant effect on production. Data collected on these parameters is highlighted in Figures 2-4. Stimulation intensity is defined in terms of proppant volume (Figure 2).

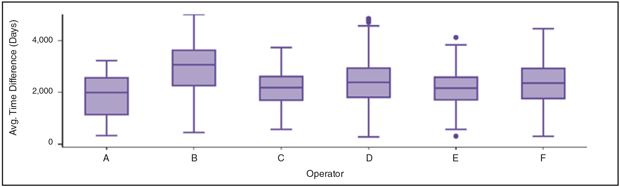

Well spacing indicated in Figure 3 is defined from the perspective of the closest child well where the “(parent) spacing” is the distance from the closest child well to the parent well and “(child) spacing” is the distance from the closest child well to the adjacent co-developed child well. Figure 4 provides the average time difference in days between the completion date of the parent and the closest child well, inferring that the reservoir depletion effect is greater for a larger time difference.

Operator Strategies

Interpreted strategies were summarized for operators. For instance, Operator A demonstrated the heaviest refracturing activity during the study period. There appeared to be a consistent strategy of sacrificial stimulation. Refracs by this operator were not integrated into infill development. Spacing strategy was similar for parent and child wells and differed from the other operators.

Operator B exhibited an aggressive refracturing program as part of infill well development, which it has since halted in preference for sacrificial stimulation. The aggressive refracturing program may be attributable to the fact that the operator has the oldest parent wells with small proppant volumes. The difference in completion date between parent and child wells is the highest for this operator, which may contribute to greater reservoir depletion.

Operator C generally stimulated wells starting farthest away from the parent and working toward the parent well with successive fracs. Sacrificial stimulation was never a part of its strategy. Stimulation design did not vary significantly for similar wells, and proppant volumes for child wells were notably higher than parent wells.

Operator D’s strategy was mixed during the period. Decisions largely were driven by surface constraints and well pad locations. The operator progressed to wider spacing between parent and child wells, but spacings are tighter and do not differ significantly over the well inventory. Child well stimulations included large proppant volumes.

The data for Operator E showed a noticeable trend of stimulating the well closest to the parent well first. Significant spacing from the parent well also was evident.

Providing wide spacing from the parent well was an obvious and consistent strategy for Operator F. In most cases, this operator stimulated the well nearest to the parent well first and child wells tended to have a relatively tight spacing.

Data also was collected to understand what formations these operators targeted for parent and child wells. Nearly 75% of parent wells are drilled into the Bakken formation, with the Three-Forks formation representing the remaining 25%. If a parent well was drilled into the Bakken, the operator may have targeted either the Bakken or Three Forks for the adjacent child well. Looking at parent-child well relationship as a percentage of the total well count, the Three Forks was targeted about two-thirds as often for adjacent child wells as the Bakken. Among all wells, 44% have a Bakken-Three Forks parent-child well relationship, 28% are Bakken-Bakken, 20% are Three Forks-Bakken and 8% are Three Forks-Three Forks.

Discussion

Development decisions and plans remain highly diverse in North Dakota. The most consistent trend evident from the study is that decisions are dictated largely based on an efficient use of capital, physical development of well pads, and early decisions of leasehold wells that limit where and how infill wells can be drilled and completed. Although development largely is guided by these principles, in 20% of cases subsurface parameters can influence the order in which wells are stimulated, and to a lesser degree, parent wells are restimulated.

A total of 184 wells (7% of the wells included in the study) were restimulated or refractured in North Dakota during the five-year period. While refrac activity as a mitigation technique has decreased, expandable liner refracs may emerge and change the trend. At least one operator in the study is increasing the number of refracs in its development plans.

However, one study found that sacrificial fracs in nearby offsets could do a comparable job of stimulating a parent well, and another study concluded that a Middle Bakken well could produce a fracture network that could adequately drain an unstimulated Three Forks lateral 450 feet away. One may infer that sacrificial child well fracs can intersect an understimulated parent well and drain the same reserves that a parent well refrac can recover. Nearly half of the sacrificial fracs in this study resulted in significant production response in parent wells.

Most operators face similar depletion challenges respective of the completion time difference between parent and child wells. Although development decisions remain largely driven by surface constraints, there are some commonalities among operators in this study.

Operators have acknowledged parent-child well FDIs, as evidenced by wider spacing of child wells in proximity to parent wells and an increase in parent-child spacing over time. Operators also appear to be stimulating nearest the parent well first where facility or scheduling constraints do not limit choice.

DARREN SCHMIDT is the assistant director for energy, oil and gas at the Energy & Environmental Research Center at the University of North Dakota. He leads a team focused on research, development and commercialization related to efficient and clean fossil fuel production, carbon management and renewable energy. Prior to joining EERC, Schmidt worked in operations and research for Equinor in the Williston Basin. He holds a B.S. in mechanical engineering.

KYOUNG SUK MIN is a reservoir engineer at EERC, focused on solving advanced challenges in conventional and unconventional reservoirs such as production mechanisms and enhanced oil recovery in tight reservoir rocks, CO2- or produced-gas-based storage, and production data analysis and interpretation for unconventional reservoirs. Before joining EERC, he served as a senior reservoir engineer at Anadarko Petroleum, Pioneer Natural Resources and Eden Geotech. Min holds an M.S. in mechanical engineering from the University of Michigan and a Ph.D. in petroleum engineering from Texas A&M University.

STEPHEN GUILLOT is a distinguished reservoir engineer in the subsurface initiatives group at EERC, where he interfaces with a diverse team of scientists and engineers to assess project uncertainties in oil and gas development and geologic CO2 storage. Prior to joining EERC, Guillot was an independent consultant and a reservoir engineering advisor for Denbury Resources. He holds an M.S. in petroleum engineering from the University of Texas at Austin and a B.S. in civil engineering from the University of New Orleans.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.