Texas A&M Validates Microproppant

LOCKPORT, LA.—Laboratory tests by Texas A&M confirm that Deeprop® microproppant from Zeeospheres Ceramics LLC significantly increases fracture conductivity, the company reports.

The microproppant is a highly spherical, very strong ceramic proppant that is about 500 mesh in size, Zeeospheres describes. Because it’s so tiny, the company continues, water suspension can carry it deep into the fracture network. It can also penetrate fractures 1/10th the width when compared with 100 mesh proppant.

To assess the microproppant’s impact on conductivity, Texas A&M performed laboratory testing on a fractured rock sample from the Eagle Ford. For that test, it coated the sample’s fracture faces with a slurry containing water and 0.018 pounds per square foot of microproppant, allowed that monolayer of slurry to dry, then evaluated gaseous nitrogen’s ability to pass through the fracture under increasing closure stresses.

As a control, Texas A&M performed the same test on the unpropped fractured Eagle Ford sample. The ceramic microproppant delivered an order of magnitude increase in conductivity, Zeeospheres summarizes.

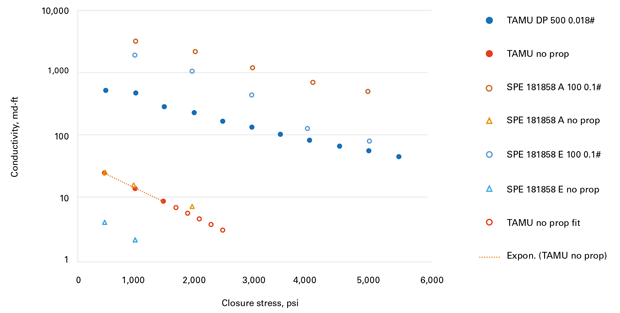

In Figure 1, the solid blue dots toward the top of the graph show the microproppant’s conductivity, while the solid red dots show the unpropped control. The control test had to end early after an anomalous spike in conductivity revealed that the sample’s edge had been chipped, the company relates. The clear red circles show best fit results.

For context, Figure 1 also contains propped and unpropped conductivity tests for two of five Eagle Ford facies that Texas A&M analyzed as part of a 2019 SPE paper, SPE 181858, “Relationship Between Mechanical Properties and Fracturing Conductivity for the Eagle Ford Shale.” These tests involved 100 mesh proppant in the lower Eagle Ford (A) and upper Eagle Ford (E). The company says the spread between the A and E facies shows how much propped conductivity can vary.

Zeeospheres points out that its 500 mesh microproppant had similar conductivities at higher confining stresses as the 100 mesh proppant, even though the tests for the latter had proppant loadings five times higher. Because it delivers this conductivity deep into the fracture network, adding the ceramic microproppant to the pump schedule often increases production more than 10% while flattening the decline curve, the company reports.

For more information, visit www.deepropfrac.com.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.