Permian Institutions Expand Industry Training And Accelerate Innovation

By Danny Boyd

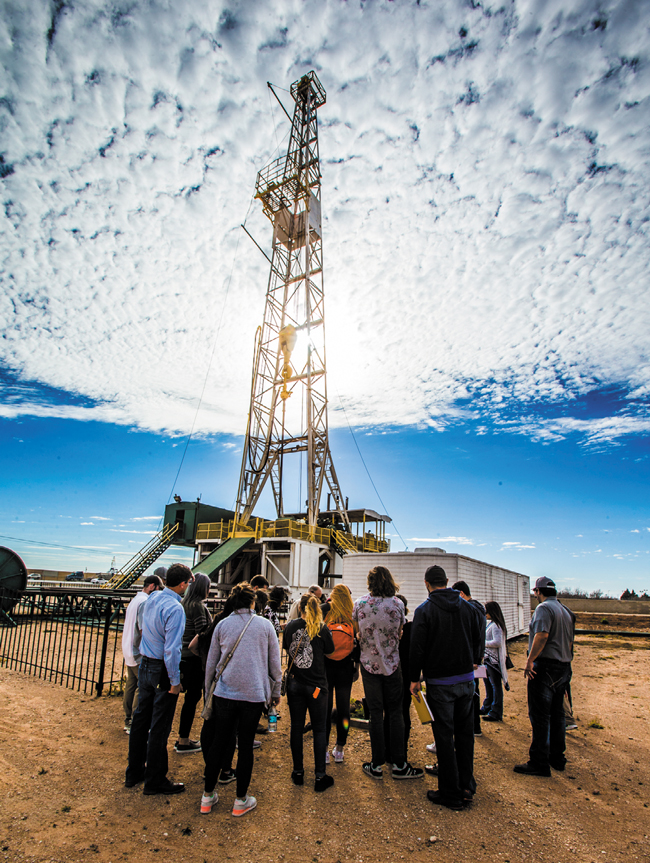

From engineers to truck drivers, the oil and gas industry continues to depend on a well-educated, trained workforce to provide the operational difference in the heart of America’s oil patch. These individuals’ hard work and ingenuity is enabling operators to experiment with new well geometries, such as U-laterals; reliably perform simulfracs and trimulfracs that demand vast quantities of proppant; and perfect artificial lift and production chemical programs to get more from existing wells.

Training also plays a vital role in the industry’s ongoing effort to improve safety. This is true whether someone spends most of their time in the field or primarily works at a factory, pipe yard, gas processing plant, chemical blending facility or one of the many other sites that help make the Permian Basin the nation’s top oil producer.

Direct oil and gas employment accounts for more than 20% of the Permian Basin’s 264,000 civilian workers in Texas alone, says Willie Taylor, chief executive officer of the Permian Basin Workforce Development Board, which distributes training and employment assistance dollars across the 17 West Texas counties that overlay the Permian Basin.

The entire region is effectively in the oil business, he points out, with producers and service companies depending heavily on a host of industrial, commercial, retail and professional workers whose efforts directly or indirectly support the basin’s petroleum-fed economic engine.

“The oil and gas industry is the economic driver of the entire Permian Basin, and I tell people all the time that the board has a simple mission: to invest in the region’s future through jobs and training,” Taylor says.

Permian Workforce

To execute that mission, the board invests funds that come from federal and state revenue, as well as private contributions. Although 65% of the development board’s $32 million annual budget is spent on childcare that benefits every employment sector, the remainder focuses on regional workforce development and training for many high-wage, high demand occupations.

Taylor says about half of the board’s 30 members come from private sector companies, such as Diamondback Energy, Chevron, Oxy, Encore, and Atmos, who work with members from education, healthcare and public agencies to identify the most acute needs.

The University of Texas Permian Basin notes it offers 11 energy-related undergraduate majors, seven energy-related graduate programs and nine certification programs, including bachelor’s degrees in land management and civil engineering that were recently added based on industry feedback.

Altogether, the board has identified 35 critical skills and crafts that warrant targeted training support, including truck driving, welding, machining, healthcare and educational work, IT automation, electrical, HVAC and plumbing.

Continually recruiting and training truck drivers is imperative as veteran drivers retire and others come and go from a region with a highly mobile workforce drawing from cities and rural communities across West Texas, Taylor says.

Board-supported training and skills development programs are offered at Odessa College, Midland College and Howard College, which is in Big Spring, Tx., Taylor says. Youth funding initiatives also include assistance for top-level career and technical programs at regional high schools.

Through the Texas Workforce Commission’s Skills Development Fund, up to $2,000 per employee can be awarded to train new workers or upgrade the skills of existing workers at qualifying companies, Taylor says.

Job fairs play a major role in attracting workers, he adds. A large job fair for veterans and their spouses will be held in conjunction with Odessa College on Nov. 11. Noting that it is now in its 14th year, Willie says the annual “Hiring Red, White and You” event has proven to be valuable for both companies and job seekers.

UTPB Program Expansions

As the Permian Basin Workforce Development Board channels funds for job training, The University of Texas Permian Basin is adding undergrad and graduate degree programs and certificate offerings to develop home-grown talent that often gets hired by some of the nation’s top producers and service companies, says Raj Dakshinamurthy, provost and senior vice president for academic affairs.

UTPB’s work supporting Permian small business development and state-of-the art manufacturing innovation also benefits oil and gas and a host of industries that undergird it.

The university, which has campuses in Odessa and Midland, now offers 11 energy-related undergraduate majors, seven energy-related graduate programs and nine certification programs, Dakshinamurthy says.

These 3D printers are among the many pieces of equipment available at the University of Texas Permian Basin’s two makerspaces and at its Advanced Manufacturing Center. The university says these resources help students, staff members and companies develop valuable skills and prototype, test and refine new products.

About 140 students are pursuing petroleum engineering degrees at UTPB in 2025, with up to 40 graduating each year. About 50 mechanical engineering degrees are awarded annually and more than 700 students have enrolled in the program over the past five years.

Bachelor’s degrees are available in chemical engineering, geology with a petroleum concentration, energy land management, civil engineering, industrial technology, computer science and environmental chemistry. The land management program is new, with its first class graduating last year, Dakshinamurthy says, noting that the program is getting national attention.

The civil engineering program launched this year to help meet the growing need among energy companies for experts in designing and building infrastructure and facilities.

“We got a lot of feedback from our community partners at the Midland Development Corporation, the Odessa Development Corporation and our local engineering firms, who reached out to us and said we really need more civil engineers in the Permian Basin,” he says.

UTPB’s master’s program in energy business, which is laser-focused on how to run an oil and gas company, continues to attract more attention, as does its M.B.A. in energy finance. The university offers certificate programs in petroleum technology that do not require prerequisites for anyone with an undergraduate degree.

High Standards

UTPB programs are accredited by what Dakshinamurthy describes as the gold standard in engineering disciplines: ABET, formally known as the Accreditation Board for Engineering and Technology. The College of Business programs are accredited by the Association to Advance Collegiate Schools of Business, or AACSB.

Input and feedback from industry partners on university boards is crucial to ensure that programs are aligned with regional needs, he says.

The Engineering Advisory Board includes representatives from Chevron, Halliburton, Terracon, ConocoPhillips, ExxonMobil and the Odessa College School of Business & Industry, among others.

Despite rigorous degrees and its pedigree in the heart of U.S. oil and gas, the university is affordable, Dakshinamurthy assures. The Falcon Free Program, named after the school’s mascot, covers tuition and mandatory fees for fall and spring terms for first-time undergraduate, degree-seeking Texas residents with a family-adjusted gross income under $100,000. Students can qualify annually for up to eight semesters of full-time undergraduate enrollment.

UTPB, led by President Sandra Woodley, is more than a university, Dakshinamurthy adds. He points to cutting-edge labs, business incubators and work through entities that include the Texas Water & Energy Institute, which anchors the Permian Basin Water in Energy Conference and studies produced water characterization, treatment and potential uses.

The university is committed to commercializing research and transferring technology by working with students and faculty and connecting faculty with companies that have similar research and development interests, says Brian Shedd, executive director for the Office of Innovation and Commercialization at UTPB’s Center for Energy and Economic Diversification.

Small Business Assistance

To support local entrepreneurs, UTPB’s Small Business Development Center provides coaching and other resources to small business accelerator programs, including the Midland Development Corporation’s Midland Entrepreneurial Challenge, Shedd says. Through this program, 46 small businesses from the city of Midland refine their business plans and compete for a share of $500,000 in prize money.

Although the competition is open to a variety of businesses, automatic acceptance is granted to businesses in energy, water, space and aerospace, all considered key industries for Midland.

Winners last year included Sable Controls, which makes custom valves and pumps for oil and gas and used the funds to order more stock and better serve customers, Shedd says. Recipients from earlier classes include the civil engineering firm Magrym Consulting, and The Oilfield Photographer, whose work has appeared in AOGR.

UTPB’s Small Business Development Center provides information and other support to enterprises across 13 counties, including oil and gas supply businesses and a variety of mom-and-pop enterprises. In other endeavors, the university is working with ConocoPhillips on the company’s Small Biz Builder program to promote and develop small businesses and entrepreneurs.

UTPB makes incubator office space available to qualifying companies that want to connect with the university and reach out to students, Shedd mentions. Laboratory spaces can also be rented, including benches in a wet lab for chemical, biological and materials research.

To promote product development, UTPB has manufacturing resources through two makerspaces available to students, faculty, staff, private companies and individuals. The makerspaces have 3D printers, laser cutters, 3D scanners and other entry-level prototyping equipment.

For those wanting to move into more sophisticated material development, the university offers its Advanced Manufacturing Center located at the Center for Energy and Economic Diversification in Midland, Shedd says. The AMC offers hands-on manufacturing experiences for students; manufacturing and safety training for companies; manufacturing, prototyping, designing, and testing for custom parts; and collaborative research.

“I call it the makerspace on steroids,” Shedd says. “It really is a university level laboratory around manufacturing and characterization. We have well over $1.5 million worth of equipment in there.”

Powerful Equipment

To meet different needs, the AMC has a 3D printer that uses a liquid resin instead of a solid filament to print 3D parts, and printers that can integrate glass fiber, carbon fiber and Kevlar fiber into 3D printed parts, including both chopped fiber and continuous fiber. Shedd says these printers create materials that resemble composites, with extreme strength and quality more akin to production-level parts than prototypes.

For developing metal parts, the space offers a metal-sintering 3D printer that can create parts out of metal, as well as a plasma cutter that can cut metal up to an inch thick. It also includes a water jet for glass and ceramics, and a CNC table router for woods, metals and plastics.

The AMC can conduct tensile and compression testing on materials and put parts through fatigue tests, Shedd continues.

“We’re starting to advertise those as being available to industry,” he says. “If we have a couple of professors that are doing some part analysis for industry, if they want to send us parts and say ‘we want to know the failure strength of this part,’ or maybe something broke and they want us to do surface characterization, we have microscopy capability to do that.”

The university’s microscopy capabilities include a scanning electron microscope for analyzing metal materials and an atomic force system that can get down to nanometer resolution to look at surface characteristics, Shedd details.

In March, UTPB created the Permian Basin Manufacturing Consortium with founding member American Industrial Machine donating a mill and lathe, Shedd says.

“The big thing that we’re offering through that support is a manufacturing training program,” Shedd says. “We just launched this for the first time over the summer. We had nine students go through the program. It’s not for a degree or certificate, but it gives students exposure and hands on time on all the equipment at the AMC.”

During training, students each week learn a piece of equipment and produce a part. In the eighth week, they test parts on Instron equipment to experience firsthand how various manufacturing techniques influence the part’s characteristics.

UTPB plans to offer the training three times a year and has 12 students signed up for fall. Out of the summer program, three students secured internships, with one working for AST Space Mobile at the Midland International Air & Space Port, which was the first U.S. airport to be licensed as a commercial spaceport.

“Our research is not about researching and publishing in a high impact journal,” Dakshinamurthy says. “Our research is applied research on how we can partner with the community and support local industry through the technology we have and through our faculty expertise. We hire faculty who complement the technological skills we are building on our campus.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.