Drilling Technology

Latest Bit Designs Drill Faster, Farther

By Colter Cookson

Human beings are exploring deep space, eradicating diseases, designing pilotless planes and cars, and placing horizontal wells with multi-mile laterals on target. Psychologists say we do so much in part because we all share a desire to accomplish big things. For the humans in the oil and gas industry, that means celebrating even their greatest successes for only a few days, then getting to work on the next challenge.

Nowhere could that dynamic be more obvious than in the world of drill bits. Instead of resting after record-setting runs, bit engineers analyze their designs’ performance to identify and address the barriers that keep them from drilling even faster and farther.

Their efforts are paying off. PDC makers say their latest designs deliver significant improvements in speed and durability by optimizing hydraulics, enhancing backup cutters, leveraging modern motors, and minimizing reactive torque. Meanwhile, the newest roller cone and hybrid bits employ advanced cutters and application-specific cutter configurations to set new standards for drilling efficiency and durability.

To drill faster, bits need to handle the additional cuttings generated by the extra speed, notes Chris Casad, innovation project manager at Ulterra. “As better PDC bits have unlocked faster penetration rates, it has become clear we need to take the next step in hydraulic performance,” he says. “Improving cuttings evacuation not only enables faster rates of penetration, but also keeps the cutters clean and cool. This minimizes thermal degradation and cutter damage, enabling the bits to maintain their high performance longer.”

According to Casad, Ulterra has advanced hydraulic performance through a new concept called SplitBlade™. The primary blades in SplitBlade bits are divided into two parts, with the inner part offset from the outer part near the shoulder. “The offset creates a recess to put a second nozzle for each blade,” he explains. “Two nozzles create dedicated flow paths from the cone of the bit and from the shoulder outward. The focused flows energize the cuttings and ensure evacuation happens quickly and reliably.

With two nozzles for each blade, the cutters on Ulterra’s SplitBlade™ bits stay clean, cool and sharp. The company adds that the two-part blades have more points of contact with the formation, which improves tool face control by mitigating torque fluctuations.

“In addition, offsetting the blades gives bit designers the opportunity to try cutting structures that previously would have been impossible,” he comments. “For example, because the offset increases the distance between the cutters, we often can double the diamond volume in areas that are seeing a lot of wear without encroaching on an adjacent cutter.”

Casad adds that the offset gives the bit more points of contact with the formation, allowing it to distribute point loads more evenly and reduce torque fluctuations. He says the smoother torque improves tool face control, cutting the amount of time spent sliding in the curve and enabling the bit to stay on target once it is in the lateral.

He highlights one other benefit: Because they are so clean, SplitBlade bits do a great job of converting weight into energy. “Like a knife, a PDC bit works by applying force to a small area,” Casad notes. “When cuttings are recirculating or building up on the tool face, they spread the weight across a wider area, making the cutters less effective.”

By applying more weight to the bit, Casad says drillers can increase depth of cut to improve performance. “Fast rotation speeds and a low depth of cut cause the bit to turn and start eating into the well bore, creating bumps and undulations. A high weight and a lower rpm let the bit drill fast, clean and smooth, meaning the wellbore will be easier to complete and produce,” he says.

The SplitBlade concept has been tested on more than 300 runs and has drilled more than 2 million feet across North America and in China, Australia and South America, Casad reports.

“The field testing started in the Eagle Ford, where operators were looking for ways to drill 15,000 feet through the curve and lateral sections without steerability issues in the curve or tracking issues in the lateral,” he relates. “When we introduced SplitBlade, we were able to combine the sections more reliably while cutting drilling times by 30 percent. The bits came out with a dull grade of 1-1 to total depth and drilled smoothly through both sections.”

While it is often used in curve and lateral bits, Casad says the enhanced hydraulics can be applied to large vertical bits as well. “This technology can translate across bit designs,” he concludes. “It will have the biggest benefit in applications with fast ROPs, but it is applicable almost anywhere.”

Advancing Hydraulics

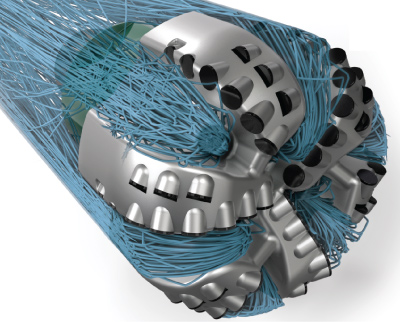

Cuttings volume, formation types and rig pressure mutually affect PDC bits’ hydraulic performance, observes Cary Maurstad, Varel International Energy Services’ marketing director. To overcome those constraints, the company employs a design process called HYDRA™ that combines computational fluid dynamics with proprietary technology. “This process is helping us improve ROP and footage drilled in challenging lithologies, including softer clays and shale, as well as sands and limestone,” Maurstad reports.

HYDRA bits’ curved nozzles direct fluid flow to the cutter surface to improve cleaning and cooling without affecting rig hydraulics, Maurstad relates. Across hundreds of applications, he says the nozzles’ focused hydraulics have reduced core outs, plugged nozzles and bit balling.

To optimize cuttings evacuation, Varel Oil & Gas Drill Bits is deploying curved nozzles and straight, webbed blades to focus hydraulic force. The company says these technologies help bits achieve longer runs with faster penetration rates.

“In addition to the nozzles, we use straight rather than curved blades,” Maurstad says. “The atypical blade geometry increases hydraulic shear stress to improve cutter cleaning and removal.”

These straight blades are webbed, he adds. “Instead of leaving open channels between the primary and secondary blades, we connect the secondary blades to the back of the primary blades,” Maurstad clarifies. “This helps contain and direct hydraulic force to the blades to limit cuttings recirculation and entrainment, and increase cuttings evacuation.”

In New Mexico, where interbedded clays, carbonates, limestones and sandstones make bit hydraulics central to efficient drilling, Maurstad says HYDRA-optimized bits have improved footage significantly, achieving operators’ fastest one-BHA runs to total depth.

In West Texas, interbedded shale, limestone and sand in the Wolfcamp formation cause coring, plugged nozzles and bit balling, and force multiple runs to drill laterals, Maurstad notes. “With Hydra, we have cut the number of bits required in half,” he reports. “The optimized hydraulics have increased footage drilled as much as 96 percent and ROP as much as 58 percent.”

Backup Cutter Layout

By optimizing backup cutter placement, Halliburton’s Stega™ cutter layout can improve bits’ cutting efficiency in hard and interbedded applications, says Brad Dunbar, the company’s drill bit product manager. In a few applications, he says the new layout has doubled ROP.

“The Stega layout achieves that by rotating the backup cutters,” he says. “As a PDC turns, each of the primary cutters creates a different path through the rock. In a traditional design, the backup cutters ride in the same path as the cutter they are behind, but contact the rock in an inefficient way. By moving the backup cutters to the other side of the bit, we give the other cutters time to create paths as well. These paths change how the backup cutters contact the rock, allowing them to do more work.”

In a traditional design, Dunbar says the backup cutters often end up cutting with their sides. “By changing the layout, we are moving the side cutting to other cutters. This applies all of the force from the weight on bit down into the axial direction of the rock, which is far more efficient than trying to drill sideways,” he relates.

By changing how backup cutters contact the formation, Halliburton’s Stega™ cutter layout maximizes their cutting efficiency. This significantly increases and sometimes even doubles drilling speed, the company reports.

According to Dunbar, the increased efficiency allows the bit to drill faster with the same weight on bit. “We accomplish that without decreasing diamond volume, so the bit achieves these increased speeds without losing any durability. In fact, the increased efficiency generally allows the cutters to drill farther,” he says.

The Stega layout increases contact points between the bit and the rock, which Dunbar says minimizes vibration that can degrade drill string components and complicate tool face control.

The layout’s benefits have been proven both domestically and internationally, Dunbar assures. “Across applications, the layout’s boost to drilling efficiency has increased footage drilled by helping the cutters stay sharp or enabled faster ROPs,” he reports.

As an example, Dunbar cites an application in Argentina where the cutter layout doubled the amount of footage drilled. To bring the benefits closer to home, he points to an 8 1⁄2-inch curve and lateral application in Upton County, Tx. Compared with offsets drilled by the same operator, the bit almost doubled ROP and run length, drilling an additional 2,400 feet at a 15 feet/hour faster ROP.

Leveraging New Motors

In the Eagle Ford, operators are deploying longer motors with slower rpms but higher torques, observes Casey Kitagawa, global applications engineering director at Drilformance. “Traditionally, the standard Eagle Ford motor for the curve and lateral had half a revolution for every gallon of flow rate. The new even-wall motors go through 0.40 or 0.42 revolutions a gallon, but they are powerful enough to handle larger depths of cut without stalling.”

To help operators drill Eagle Ford curves and laterals quickly, Drilformance has developed an aggressive bit that can take advantage of the power delivered by long, high-torque mud motors. According to the company, the bit delivers rapid build rates in the curve and tracks well in the lateral.

Taking advantage of the motor’s strength requires new, more aggressive bits. With that in mind, Kitagawa says Drilformance developed an 8 3⁄4-inch, six-blade bit for drilling Eagle Ford curve and lateral sections in a single run. Unlike traditional designs for the application, which use 11-millimeter or 11.5 and 13-millimeter cutters, or in some cases a mix of 13- and 16-millimeter cutters, the new bit only contains 16-millimeter cutters in order to maximize ROP.

The company has made more than 25 runs with the bit, a DF616 STX. Based on its success, Kitagawa says Drilformance created an 8 1⁄2-inch version that has completed more than 13 runs. “Many of the directional drillers for these runs say the bit is their favorite to use in the Eagle Ford because it can get the yield and build rates they need in the curve while tracking well in the lateral,” he reports.

In its first run, the 8 3⁄4-inch DF616 STX drilled the entire 12,872-foot curve and lateral sections of a horizontal well in Dimmit County, Tx., at an average ROP of 220 feet/hour. The fastest offset run on the same pad required two bits to complete those sections and did so at a combined ROP of only 154 feet/hour, Kitagawa relates. He adds that the Drilformance bit set a record by completing the curve in five hours, rather than six or seven.

Midland Basin Bit

The kickoff points for Midland Basin wells targeting the Wolfcamp and Spraberry occur at depths between 7,000 and 10,000 feet, Kitagawa notes. “In the deeper areas, where the casing point is at 8,000-9,000 feet, many operators need three or four bits to drill the vertical interval,” he says. “We have developed a bit that can do it in one or two runs, which generally cuts one or two days of rig time.”

The 12 1⁄4-inch bit has five blades and 16-millimeter cutters. “Traditionally, the bit would use six or seven blades to increase the diamond volume and durability,” Kitagawa allows. “We decided to take an unusual approach after analyzing dull bits and realizing that the damage came from their poor steerability. To achieve the 8-12 degree tangents operators required, the bits had to build and drop constantly, which stresses their sides and shoulders.”

The tangent-friendly five-blade bit has completed almost 40 runs, and Kitagawa says its performance has been exceptional. For example, on a four-well pad in Martin County, Tx., the bit drilled from 1,346 feet to a depth of 7,253 feet, 30 percent farther than the three offsets’ average.

In another area, two rigs with the new bit outperformed two rigs using a more traditional design, Kitagawa says. All four rigs were within a mile of one another. On average, the Drilformance bit increased run lengths by 20 percent while maintaining faster ROPs.

Tackling Interbedded Formations

By investing in research and development throughout the downturn, National Oilwell Varco’s ReedHycalog business unit reports it has stayed ahead of operator efficiency demands. “We have made several improvements to our Tektonic™ PDC bit platform that simplify drilling in a variety of formations, from shale plays to offshore salts,” says Tom Roberts, ReedHycalog’s director of PDC strategy.

Those innovations include novel multidimensional PDC geometries that maximize ROP, torque-minimizing depth-of-cut control inserts and new diamond grades that are effective in nontraditional PDC applications, Roberts details.

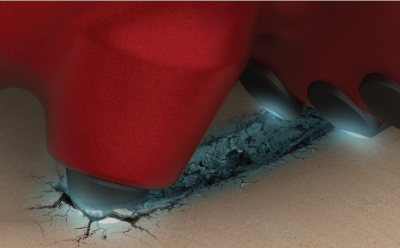

As part of a strategic project focused on drilling salt, the company developed a nonplanar cutter design called ION™ 4D. Pressurized drilling lab tests show that the new cutters significantly increase ROP in all rock types, Roberts reports. He explains that they fracture the rock in point-loading through a crushing action on the cutting edge, then plow with relieved surfaces in the shearing direction. The ramp on the cutter's noncutting side helps evacuate cuttings.

In their first field test Roberts says the ION cutters increased ROP by 20 percent in a Williston Basin well. They were applied to an 8 3⁄4-inch, six-bladed, 16-millimeter design for drilling the bottom of the vertical section, and they helped it drill 1,974 feet to a measured depth of 10,050 feet at an average ROP of 160.9 feet/hour.

ION™ 4D cutters from National Oilwell Varco’s ReedHycalog business unit improve penetration rates by crushing and fracturing rock before shearing it. The company says the cutters are advancing PDC bit performance alongside uniquely-shaped depth of cut inserts and more durable diamond grades.

New TORC™ inserts control depth of cut to mitigate stick-slip and improve tool face control while maximizing ROP, Roberts continues. “These inserts have a unique shape and a larger surface area that allows them to control depth of cut more effectively than traditional depth-of-cut control inserts,” he says. “In fact, they reduce torque fluctuations as much as 50 percent.”

NOV tested the inserts in a highly interbedded interval near Pinedale, Wy., where compressive strengths fluctuated between 10,000 and 30,000 psi. With the inserts, a 6.0-inch, six-bladed, 13-millimeter design drilled from a measured depth of 12,647 to 13,915 feet for a total interval of 1,268 feet, Roberts reports.

“This was 20 percent longer than the average offset,” he remarks. “Given how far it drilled, it is remarkable that the bit came out with an exceptional dull grade of 0-2-WT. It had an average ROP that is typical for the area.”

Alongside the multidimensional cutters and depth-of-cut features, Roberts says ReedHycalog has been iterating diamond grades for application-specific cutters. He highlights a new grade with exceptional thermal resistance that has shown promise for drilling with air in the Northeast, an application traditionally reserved for roller cones.

The thermally-resistant cutters were tested in a Marcellus Shale tangent/curve interval. According to Roberts, the bit drilled from 2,068 feet to 6,560 feet for a total of 4,492 feet in 39.75 hours, and came out with a dull grade of 0-3-CT. “That grade is excellent,” he assesses. “The bit performed so well that we expect drilling the interval with PDCs to become the standard practice.”

Next-Generation Hybrid

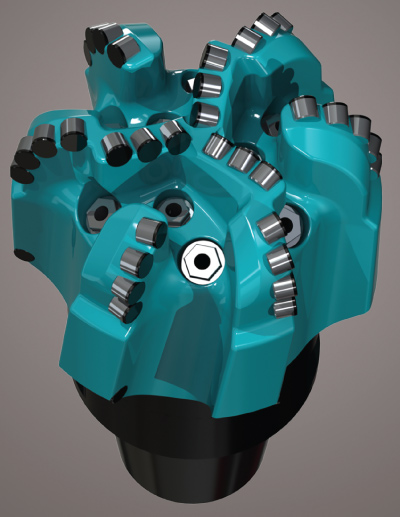

Drawing on 10 years of experience designing hybrid bits, Baker Hughes, a GE company, has introduced the Kymera™ Mach 4 hybrid drill bit, a roller cone and PDC hybrid for drilling through soft to medium-hard formations. Shelly Cory, the company’s Kymera product line manager, says the bit improves on its predecessor enough to increase penetration rates by 25 percent or more while providing even better durability.

“Kymera Mach 4 is designed to drill beyond the curve. It has been deployed in vertical, curve and lateral sections, and in many applications, it can handle combinations of those sections,” she says.

The Kymera™ Mach 4 hybrid bit offers even greater speed, durability and tool face control than its predecessor, according to Baker Hughes, a GE company. BHGE credits the next-generation hybrid’s strong performance in part to a higher blade count and greater diamond volume, as well as features that reduce lateral vibration.

Like its predecessors, Kymera Mach 4 combines rotating roller cones with PDCs. “The roller cones crush the rock, relieving the compressive strength so the PDC cutters can shear more effectively,” Cory explains. “We have a decade of proof that this dual cutting mechanism improves drilling efficiency.

“It also improves tool face control,” she continues. “Instead of being fixed, the depth of cut is in the roller cones, which adjust to what they are encountering. That lets the hybrid go through interbedded formations and tough stringers without the reactive torque and drilling dysfunctions a PDC would experience during transitions.”

Cory says the Mach 4 includes several design improvements that contribute to its tool face control, durability and speed. “By increasing the blade count and optimizing the diamond volume, we have reduced lateral vibrations, which improves both durability and hole quality,” she illustrates.

“We increased the diamond volume by adding recessed cutters called ShadowCut,” Cory continues. “Having more diamond in the shoulder next to the cone that rotates makes drilling more balanced, which is one of the ways we minimize lateral vibrations.”

Tougher carbide grades on the cone boost the bit’s durability, Cory says. For particularly lengthy runs, she says the PDC cutters can be made with materials that have exceptional wear and thermal resistance, as well as a shape that increases impact resistance.

Kymera Mach 4 bits have completed more than 120 runs worldwide ahead of their commercial debut, Cory reports. “We have had fantastic runs in West Texas and Oklahoma, as well as Canada, Oman, Kuwait, Saudi Arabia and the North Sea,” she details.

Cory highlights a Permian Basin water well in Culberson County, Tx., in which a 12 1⁄4-inch Mach 4 went 78 percent faster and 389 percent farther than offsets. This enabled the driller to complete a section that previously required 11 bits with only two.

“In a deepwater North Sea well, we had an operator who needed to complete a 16-inch section with a 70-degree inclination,” Cory says. “Because the section included soft gravel interbedded with hard sandstone and coal stringers, the PDC previously used had trouble with tool face control and durability. With the Kymera, the operator held the tangent while drilling 40 percent faster and 14 percent farther.”

Gouging Hybrid

Shear Bits reports that it continues to refine the design for its Pexus™ hybrids, which protect PDC cutters with gouging inserts. “These inserts fracture the formation ahead of the cutters, reducing the amount of impact damage they take,” says Wayne Miller, the company’s sales and operations manager. “They also smooth torque, so the motor and other tools in the bottom-hole assembly see less vibration.”

Shear Bits’ Pexus™ inserts gouge the formation ahead of the PDC cutters, protecting them from impact damage and allowing them to shear more efficiently. Because the inserts extend bit life, the company says they increase penetration rates and footage drilled in a variety of applications, including intervals with tough or highly-interbedded formations.

While the gouging hybrids originally were developed to drill through gravel and boulders normally only drillable with roller cones, Miller says Shear Bits has adapted the concept to a variety of applications, including formations traditionally drilled with PDCs. In long, highly-interbedded intervals, he says the hybrids’ ability to extend cutter and BHA life often translates into higher ROPs.

“We also are replacing PDCs in intervals where the formation is tough throughout. In this situation, PDCs are used over roller cones because roller cones can drill only so many hours before their bearings wear out,” Miller says. “Our hybrid offers steerability and durability comparable to a roller cone, but can stay in the hole much longer.”

Since their debut in 2013, Miller says the gouging hybrids have completed more than 1,400 runs and drilled 3.5 million feet of rock. To show how well they perform, he cites a case in Canada where the bit had a direct offset drilled by the same operator using the same BHA and well profile.

“After drilling the vertical section, the operator would pull out of hole and put on a new BHA to drill the curve,” Miller recalls. “The interval is tough and full of transitions, so for the offset, the operator used a roller cone hybrid to minimize torque and vibration that could compromise tool face control. It drilled 764 feet at an average speed of 28 feet/hour.

“The Pexus had comparable vibration and tool face control, but drilled 1,168 feet at an average speed of 38 feet/hour,” he reports. “Because of the gouging action’s efficiency, it also required 65 percent less weight on bit.”

Another Canadian operator chose a gouging hybrid to drill laterals in an area with abrasive sands containing hard dolomite stringers. According to Miller, most of the offsets drilled 1,000-2,000 feet. By prefracturing the rock and keeping the cutting structure sharp through the stringers, the Pexus not only drilled the first lateral leg, but also pulled back into the hole to perform an open-hole sidetrack and complete the second leg to total depth on the same BHA.

“In total, the hybrid drilled 9,000 feet,” Miller reports. “This is one of the first times we have seen any bit complete both a lateral and a sidetrack through dolomite stringers, and it did it at an ROP about 30 percent faster than the offsets.”

Miller points out that Shear Bits is adapting the gouging hybrid concept to remove frac plugs and sleeves. “Because frac plugs and sleeves have so many components and parts, there are a lot of interrupted cuts,” Miller says. “Gouging inserts can protect the cutters and help them transition from one material to another.”

In one application, the plug and sleeve bit drilled 30 percent faster than roller cones and 43 percent faster than reverse clutch mills, says J.J. Herman, the company’s co-founder. In another, a single bit drilled 34 frac sleeves before being pulled out of hole to drill seven more in another well.

“The strength of the gouging mill is that the cutting structure stays sharp from the beginning of the run to the end,” Herman comments. “As a result, it maintains higher efficiency and gage throughout, making it easier to put tools down the well in the future.”

Roller Cone Inserts

Leveraging more than a century of research and development, Smith Bits, a Schlumberger company, reports it has developed roller cone cutter configurations that withstand high temperatures and long run times when drilling through soft to ultrahard formations.

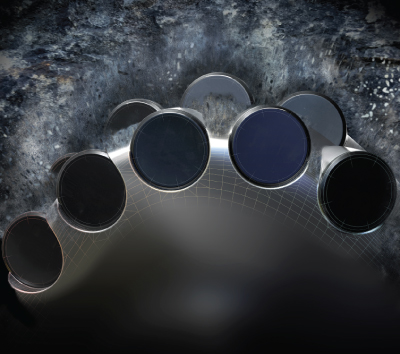

As an example, Bit and Drilling Tools Product Champion Wiley Long presents the Xplorer Helix™ spiral tungsten carbide insert configuration for the company’s premium performance roller cone bit family.

Arranging tungsten carbide inserts in a spiral array improves roller cone bits’ cutting efficiency by putting more inserts into contact with new rock. Smith Bits, a Schlumberger company, says this innovation increases drilling speed in many applications by 20-50 percent.

“Conventional cutting structures feature concentric rows of teeth that create ridges of rock. This works, but the teeth often track into grooves and craters in between the ridges,” Long says. “In addition to wasting energy, tracking can damage the inserts. By staggering them in a spiral array, we put more of the inserts into contact with new rock, limiting damage and increasing cutting efficiency.”

Field tests confirm that this spiral configuration reduces damage and improves ROP, Long says. He indicates the ROP increase generally exceeds 20 percent, but can exceed 50 percent in the right applications.

“We developed the Xplorer Helix configuration using our integrated dynamic design and analysis platform,” Long notes. “It took careful planning and modeling to optimize the drilling dynamics and ensure that staggering the inserts would not interfere with the patterns on the bits’ other cones.”

Long says the Xplorer Helix configuration is available globally, and has been applied in multiple environments around the world.

For example, the Kuwait Oil Company selected an Xplorer drill bit with the Xplorer Helix configuration to increase ROP while drilling 4,500 feet intervals through interbedded soft and hard formations. The operator needed to drill a 28-inch vertical section from 500 to 5,000 feet through limestone, dolomite, anhydrite and shale layers, Long details.

Because this section had unconfined compressive strengths ranging from 6,000 to 24,000 psi, Long says previous bits’ cutting structures would break and chip, which reduced penetration rates. “With the spiral configuration, the cutting structure, seal and bearing lasted long enough to drill the section in one run. This saved four drilling days and increased ROP by 107 percent,” he reports.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.