Tech Trends

ERP Systems Designed for Upstream Improve Efficiency, Flexibility

By Mark Hill

TULSA–Let’s talk about the elephant in the room, or more appropriately, the elephant in the datacenter. When it comes to enterprise resource planning, the energy sector is stuck in a rut with companies falling into one of two categories: Those that still manage their business on old, broken technology and spreadsheets; and those with the resources to adhere to an ERP approach that offers broad capability, but strands them in a high-cost structure that puts their business agility in chains.

ERP software is one of the most important technology choices an oil and gas operating company can make. It impacts all facets of corporate health and wellbeing, including general and administrative, operational expenses, employee satisfaction, vendor relations and competitive advantage. It is also central to an organization’s ability to pivot and adapt to our industry’s ever-changing market conditions.

For a decade, operators in the oil and gas industry have pinned their hopes largely on “big box” ERP initially developed for non-oil and gas applications, but traditional ERP software ultimately leaves energy companies with a million-piece LEGO® set and the joy of assembling it. And with every piece assembled, yet another link is forged in a chain that ties down the organization with unrestrained costs, making it impossible to move quickly. It’s not what the oil and gas business needs in today’s evolving world, and it’s also not what investors are looking for.

Enterprise resource planning is a concept that grew out of large-scale manufacturing and high-volume transaction industries such as building passenger jets or selling a smart phone worldwide, where complex supply chains and multinational accounting must be automated and optimized at every moment spanning hundreds of business processes. Despite our industry’s unique complexity, the supply chain and accounting requirements for drilling and operating wells (which may span 30 discrete business processes) really are not that complicated in comparison. Their complexity is more in the physical nature of the industry’s products and the locations where they reside.

For larger energy companies, the ERP concept tends to be well known in the C-suite as a method to manage assets at scale, gain visibility into financials, and optimize capital and operating expenses. Instead of dozens of point solutions, larger energy companies have gravitated to ERP software developed decades ago as an on-premise suite of applications. While the technology undeniably has created robust and reliable capabilities to manage the digital and physical oil field under a steady-state market, it also can require an army of consultants to deploy and comes with a bloated box of building blocks, providing cost and complexity overkill while still leaving the industry with underwhelming capability and being disconnected from the most important physical commodity capabilities that address the industry’s challenges.

The Right ERP Fit

Is ERP technology that was designed for the scale of Walmart or Boeing the right fit for managing a producer’s oil field assets, logistics and transactions? The answer is less about whether an ERP solution is purpose-built for oil and gas and more about complexity. In a cyclical industry where there’s often nothing “super” about a super cycle, hundreds of millions of dollars can hinge on a company’s ability to adapt and move.

Traditional ERP software has come at a high cost that falls into two buckets. First, the software is expensive and complex to license. Second, the timelines and complexity to actually deliver and support these systems can take years, requiring a massive commitment from energy companies in terms of internal resources (time and cost) as well as the significant outlay required for consultants.

It can be argued that there’s a third cost: opportunity cost. What’s the net present value and cost/benefit? Oil and gas companies cannot miss out on business opportunities because of multiyear software deployment that sacrifices business agility and impacts returns on capital deployed, and keeps valuable staff tied up. The opportunity cost intensifies as companies are hit with industry down cycles and find themselves weighed down by an unwieldy ERP technology cost apparatus. Cash flow is king in a depressed market, and the last thing a company needs when trying to stay afloat is to be weighed down by technology chains.

The underlying technology driving big-box ERP software never really evolved to meet the specific demands of the upstream oil and gas industry. Rather than designing a platform that adapts to the needs of oil and gas companies, energy professionals have been forced to adapt the way they work to their ERP systems, a top-down approach that fails to meet individual business needs. In this situation, the net gain in business performance of adopting ERP tends to be a wash at best, while handcuffing oil and gas companies to a cost model that is simply not viable.

Moreover, because traditional ERP was not designed based on the industry’s needs, it cannot cover all the required ground. The LEGO set that is well-suited to build transaction management and logistical workflows simply has nothing in the box for the most critical assets of all: land, lease holdings and physical production. Turns out, traditional software is better equipped to track lightbulbs and baseballs than leases and barrels, leaving energy companies with the additional cost and hassle of integrating fit-for-purpose, but incomplete solutions.

Transitioning To The Cloud

It is no longer debatable that the cloud is the best place to run business software and power oil and gas workflows, and this is absolutely the case for ERP. A recent report by Accenture cites that 90% of enterprises have made the transition to the cloud, but only 30% report having fully realized the expected value. It seems after a decade of a “cloud first” digital transformation movement in ERP solutions, companies are still chasing value. Why?

The report also ranked the top business drivers for companies that moved to the cloud, including cost-efficiency, service quality, and risk management. However, the top driver reported by most businesses was speed to market, and for the oil and gas industry, this has never been truer. It is a threefold problem for big-box ERP software:

- The software framework is so bloated and complicated that it takes a couple of years to deploy;

- The business model weighs down energy companies with massive costs that hold back the organization, no matter how much it optimizes cash flow or business processes; and

- A disruptive user experience forces energy professionals to rethink the way they work.

Given the rigidity of traditional ERP systems, imagine what it takes to make changes as business needs evolve, or tax and regulatory reporting requirements change. That is why so many users resort to working outside the system and rely on spreadsheets to get their jobs done. And on the last point, it is generally agreed that organizational change management is one of the top reasons such ERP projects fail to deliver value on time and on budget.

Today’s energy businesses, propelled by rapidly shifting economics and new operational challenges, cannot afford to be handcuffed to bloated technology that cannot keep pace. And it cannot be underscored enough that a client-centric, technology partnership is just as key to delivering business value as an ERP’s features and functionality.

Moreover, oil and gas companies do not want to be caught in the dilemma where they face stranded costs and an urgency to undertake expensive upgrades to implement traditional ERP processes to the cloud. This represents a carrot at the end of a stick tempting energy companies with better business agility and cost efficiency, but doing so by adding yet another investment link in the chain that binds them to their existing platforms.

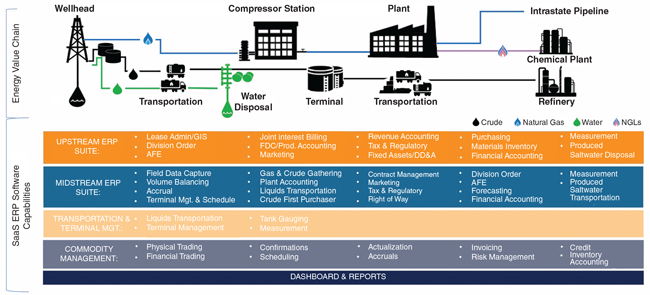

Wouldn’t it be much more ideal if the ERP platform itself was engineered specifically for oil and gas business workflows with cloud-based functionality at its very core? Wouldn’t it be even better if such a platform could be optimized and customized in the most timely and cost-efficient manner possible based directly on individual oil and gas company requirements and real-world experiences? Of course, that is precisely the premise behind a new breed of industry-centric, fit-for-size ERP technology for upstream and midstream operations (Figure 1).

Purpose-Designed Solution

The new generation of ERP technology cannot come at a better time for producing companies. As the past year has demonstrated all too well, cost efficiency is a business driver in upstream and midstream operations just as much as speed to market and flexibility, but perhaps driving costs out of the organization is a function of its agility and ability to rapidly meet evolving business conditions head on.

ERP technology is especially needed now as the industry shifts increasingly toward a business model that is akin to manufacturing, which may offer slimmer margins in exchange for greater sustainability and reduced business impacts from boom-and-bust cycles. To do that, the industry needs to automate manual processes across the value chain while embracing good manufacturing practices, where lifting costs no longer dictate whether a basin is economic one day and not the next.

One thing users have learned from traditional ERP software is the value in centrally managing workflows. This can only be further improved in the cloud. What does that look like for upstream companies? Deploying advanced analytics to optimize field operations on the cloud alongside related workflows enables production operations and accounting teams to simplify asset management, allocation, sales reconciliation and reporting while closing the month faster than ever.

The benefits extend to revenue accounting as well. By integrating production and revenue accounting into the same cloud-based solution that shares a common and consistent dataset, division orders and payments to interest owners can be rapidly processed. And by tracking the movement of crude, gas and natural gas liquids volumes and sales through a single platform, operators gain powerful capabilities to audit and trace revenue at every stage.

The new unified and purpose-designed upstream ERP solution was built on the cloud and offers scalability and affordability while accelerating data acquisition, processing, allocation and financial reporting. By eliminating data silos and manual processes, operators finally can connect the field with the back office to gain the up-to-date view of production and revenue they need to manage cash flow, accelerate revenue disbursement, and keep pace with evolving tax and regulatory standards.

A similar argument can be made for pulling midstream workflows together within the ERP system to manage gathering, transportation, gas processing, storage, and energy trading and risk management. While many integrated energy companies have spun off midstream assets over the past decade, there is still a need to encapsulate both upstream and midstream business processes under a single, unified ERP. A full oil and gas ERP can handle everything from plats and production management to plant accounting and rights of way.

Software-As-A-Service

There is an interesting parallel between traditional ERP software and the digital oil field. For years, the industry strove to apply information technology to automate and optimize core upstream drivers such as finding and unlocking hydrocarbon reserves. Digital oil field technology was largely limited to the majors at first, leaving the benefits of drilling faster and more profitable wells out of reach for most independents. Likewise, ERP software largely has been limited to a relatively small group of large operators that could afford the capital outlay and ongoing operating costs, including hiring full-time ERP experts.

Smaller, nimbler independents also have not wanted to get locked up in a multiyear IT project that handcuffs them to one technology, which is why so many pieces of the ERP puzzle continue to be handled in myriad point solutions. For most companies, “don’t fix it if it isn’t broken” has worked just fine, until now. Cloud software, or software-as-a-service (SaaS), has leveled the playing field for independents. This has led to reimagining ERP on the cloud in a way that checks all the boxes for providing innovative, out-of-the-box upstream SaaS, including affordability, sustainability and simplicity for users.

With nearly 10,000 wells across the United States, one energy company recently took the road less traveled, and embraced the new SaaS ERP model for its extensive upstream and midstream operations. The system it selected for its vast oil and gas operational footprint integrates a full financial suite, including financial statements, accounts payable, accounts receivable, revenue accounting, cost accounting, authority for expenditure, purchasing, fixed assets, accruals and forecasting. It provides upstream-specific workflow capabilities for production accounting, land management, division order, expense distribution, wellhead balancing, materials management and asset retirement.

Moreover, the company has deployed gas plant accounting, contract management, volume balancing and payout components across the cloud-based ERP system to support its midstream operations, and tax and royalty reporting components to manage its complex state and federal filing requirements. The solution provides an all-in-one, flexible SaaS ERP built to scale, enabling cost efficiencies and operational competitive advantages.

The energy-focused SaaS ERP model is perfectly poised to bring exactly the right levels of business and cost efficiency the industry needs right now without the risks associated with multiyear ERP implementations and commitments, while providing the framework to position oil and gas companies for success in the future as oil and gas markets recover.

After all, the quickest way to move backward is to stand still. Big-box ERP solutions do not necessarily lack innovation, but they are years in the making and implementing. Today’s energy sector simply does not have time for that. A company’s ERP capabilities should evolve as its business and the broader industry evolve. The new cloud-based ERP technology provides a roadmap to the future and delivers energy-specific core functionalities such as next-generation measurement data management. And its ongoing development is a partnership with oil and gas companies that embraces client requests for additional capabilities and provides a process for delivering them quickly to all users through simple upgrades.

Wall Street is looking for foundational change in the oil and gas sector. Regaining the attention and confidence of investors requires oil and gas operating companies to consistently deliver returns, focus on ESG, and pivot to new business models. A company’s choice of ERP technology can play a critical role in meeting these goals while enabling producers to operate at peak efficiency with a lean team and be ready to capitalize on the next business cycle.

Mark Hill brings nearly three decades of experience as a senior executive, sales leader and technology thought leader to W Energy Software, where he serves as chief revenue officer. Prior to joining the company, Hill was senior vice president of global sales and marketing at P2 Energy Solutions and served as vice president of sales at Allegro Development. He also has held leadership, sales and technology positions at Ikon Science, Divine (formerly Sagemaker) and leading energy companies such as Calpine and Dynegy.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.