Firms Advance Productivity, Logistics

By Colter Cookson

Hydraulic fracturing has come a long way. From the blender to the pump, every piece of equipment on a frac site has capabilities that would have seemed amazing a decade ago. Thanks to increasingly affordable diagnostic techniques, digitized data collection and powerful software, completion teams can make real-time adjustments to improve production and squeeze downtime out of even the most complicated jobs.

“The industry is past the point where we worry about whether we can pump 20 or 22 hours a day,” suggests Akshay Sagar, president of Universal Pressure Pumping Inc. “We consistently achieve that on multiple operations. The gains for pumping more will be minimal, so today, the key is keeping everything running reliably and figuring out how to improve well productivity.”

Well productivity has fallen short of expectations for several operators, he notes, especially on the second-tier acreage that many acquired when private equity-backed firms exited the market. “This has helped the pendulum swing from an extreme focus on cost to a healthy middle ground where cost still plays a role, but people want to invest in science and long-term performance,” he assesses.

Sagar cites the example of sand. “Many customers are beginning to ask how much they should rely on in-basin sand,” he relates. “In-basin sand costs less than proppant that has to be imported, but the higher-quality proppant sometimes justifies its cost by improving well results.”

To ensure crews complete tasks the right way, Universal Pressure Pumping is implementing digital tools that provide feedback and issue alerts when something seems off. The company says these process control efforts work alongside training programs and expanding automation to help its spreads deliver consistently high performance.

To help operators achieve higher returns, Sagar says Universal has created a solution engineering group that can recommend changes to everything from chemistry to perforation design and treating pressure. “We have some amazing people doing that work,” he says. “We also have increased the number of engineers we hire across the board through a focused recruiting effort that targets field engineers and other subject matter experts.”

Consistency

While the investments in science are paying off, Sagar indicates they must be paired with high-quality assets that can deliver consistent performance. By investing in more effective training and digitizing operations, he says Universal is raising the bar across its fleet. “Two years ago, we often would see wide variations in performance from spread to spread, with some delivering fantastic results but others encountering challenges,” he recalls. “Today, the performance is great across our fleet. Day after day and month after month, we are seeing very high efficiencies.”

Sagar attributes that repeatability in part to digital tools that provide more robust feedback. “We can use software to design an effective job, then monitor how it performs in real time,” he reports. “We also can look at the performance of our equipment 24 hours a day to make sure all the pumps and other components are running as they should.”

Much of the monitoring now occurs in operations centers that receive information from the field and communicate through Universal’s satellite network, Sagar says. “This gives us high-bandwidth access to data and transmission, allowing us to look at what is going on and provide support when it’s needed,” he explains.

“We have a large push across the organization to simplify and improve the effectiveness of process control so that everybody is doing work the right way,” he continues. “As an example, we have implemented a digital inspection process using a third-party app that combines video with artificial intelligence. The videos go to a cloud-based platform for analysis. If the AI notices that a blender inspection or certain other tasks were done incorrectly, it sends an alert to supervisors so they can intervene.”

The digitization effort initially faced resistance to change, but Sagar says the misgivings have passed. “Today, we are seeing enthusiastic adoption because people have had a chance to see how it can make their lives much easier,” he says. “They get access to information quickly, without inefficient extra steps and paperwork.”

Sagar says Universal is positioning itself to automate pumping operations by investing in its control platform architecture. “Automation will be a multistep process, but we are already at a stage where can move some people from the field to remote operations centers,” he relates. “This improves their quality of life and reduces safety risks while allowing us to be more flexible with our resources.”

Universal also has invested heavily in dual-fuel equipment. “Two years ago, 30% of our fleet was dual fuel capable. At the end of the third quarter, 80% will be,” Sagar details. “Dual-fuel equipment has a greatly reduced emissions profile and is generally more economic than diesel-only systems.”

In the long run, Sagar says Universal envisions performing many jobs with 100% natural gas. Toward that end, the company is exploring next-generation technology that has had positive initial results. “These next-generation platforms require a significant capital investment, one we can make only with customer commitments,” he mentions. “However, their benefits are strong enough that, over time, they could lead to a significant fleet transition.”

Electric Fleets’ Appeal

Electric fleets offer several advantages, says Sam Sledge, chief executive officer of ProPetro, a Permian-focused company that provides pressure pumping, wireline and cementing services. “Electrified equipment provides much more power density, significantly longer asset life, a smaller footprint, lower operating costs and a better emissions profile,” he clarifies.

Sledge calls the horsepower density essential to keeping pace with completions intensity. “During the past 10 or 15 years, the typical Permian Basin completion has expanded from a daylight operation with 30,000 or 40,000 horsepower on location to a 24/7 operation with 70,000 or 80,000 horsepower on location,” he recounts. “Today, a large pad may need 20-30 diesel or dual-fuel pumping units. With our new electric fleets, we can do the same job with half as many trailers.”

Sledge explains that each trailer carries two 3,000 horsepower pumps instead of a single 2,500 horsepower pump. The pumps and their electric motors also require far less maintenance, Sledge suggests. “To put the difference in perspective, think of a two-cycle motor in a weed eater and an electric motor in a ceiling fan or a fridge,” he poses. “While the weed eater needs attention, the electric motors will run for years without any.

“Our electric fleets’ components have long lives,” Sledge adds. “The turbines and power generators that provide the electricity can last as long as 20 years, and the electric motors on each pumping unit may live 10. That is a big improvement from diesel engines, where the average is somewhere between four and six years.”

The electric equipment’s horsepower density means that fewer people need to be on site during operations. In conjunction with less maintenance work, Sledge predicts this will improve safety.

Because the fleets generate power using natural gas, their environmental impact will be lower than diesel fleets, Sledge continues. “Beyond those emissions reductions is a significant economic benefit to using a lower-cost fuel in natural gas. It could create upwards of 20% of an indirect price decrease to our customers,” he reports. “Given how well safety, environmental and economic incentives align with e-fleets, we are confident the transition to them will be sustainable.”

Sledge acknowledges that electric fleets cost more to build than dual-fuel equivalents when accounting for power generation. “However, the opportunity to pull costs out and earn over a longer period outruns the extra upfront investment,” he assures.

“That said, we are doing something unique for our first four e-fleets,” he relates. “Instead of spending $40 million-$50 million before we even deploy an electric fleet, we have created a commercial agreement with our manufacturer that allows us to lease and pay for the equipment during the initial contract. This lets us spread our capital costs across time and match them to the revenue the fleets will generate.”

While he expresses excitement about electric fleets, Sledge says dual-fuel spreads will continue to be a vital part of pressure pumpers’ offerings. “Electric will not be for everybody,” he predicts. “It will appeal to operators who have the large completion programs and well inventories to make the long-term commitments we need to invest in the equipment. Dual-fuel fleets will step in for smaller programs or ones in areas where getting natural gas is impractical.”

ProPetro’s first two electric fleets should arrive in the third quarter of this year, with two more following early next year, Sledge projects. “By the first quarter of next year, more than two thirds of our spreads will be electric or dual fuel,” he concludes.

Proppant Quality

It can be easy to focus on completing wells as quickly and affordably as possible, especially when times are tough, acknowledges Carl Montgomery, a senior engineer with NSI Technologies. This cost-cutting philosophy frequently extends to proppant. “That can be a big mistake, because the quality of the proppant has a huge impact on the well’s economics,” he advises.

Montgomery explains that high-quality proppant is essential to maintaining conductivity. “Conductivity is ultimately what a frac job is about,” he emphasizes. “We are paying for trucks, water, chemicals and sand to create conductivity beyond what the well provides.”

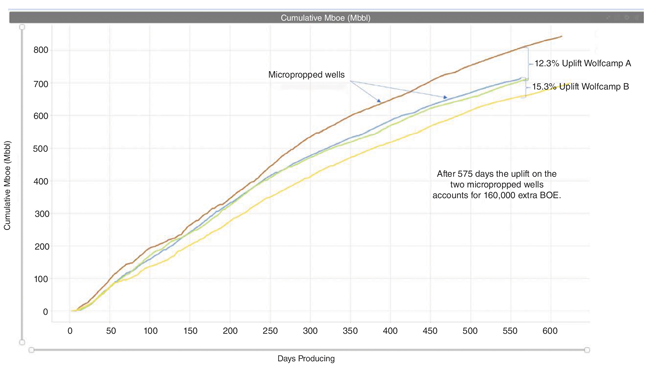

By propping fractures that are too small for even 100 mesh to enter, microproppant can significantly improve wells’ production, NSI Technologies reports. As an example, the company offers this chart, which compares two micropropped wells targeting the Wolfcamp in the Delaware Basin with two adjacent wells that lack microproppant.

As wells deplete and pore pressure drops, the closure stress exerted on the proppant will increase and eventually crush it, Montgomery notes. The production gains from higher-quality proppant come in part from its ability to endure higher stresses. To show how significant the difference can be, Montgomery cites a test comparing several types of proppant. “Once the closure stress got above 6,000 psi, the unwashed in-basin sand lost all conductivity. At the same stress, the in-basin washed sand retained 20 millidarcies of conductivity and 100 mesh had around 60,” he describes.

Montgomery frequently recommends augmenting traditional proppant sizes by leading with a ceramic microproppant provided by Zeeospheres™ LLC. “This microproppant can get into fractures ten times smaller than 100 mesh can enter,” he says. “Because it is small and light, it is easy for water to carry far into these tiny fractures.”

Wells that use the microproppant can prop far greater areas, Montgomery reports. “In the Eagle Ford, the microproppant can increase the propped fracture area by 1,500 square meters. In the Utica, it’s about 818 square meters,” he illustrates. “Both of these numbers are for a single fracture. Apply them across a horizontal well where every stage has 8-12 clusters that generate numerous fractures, and the extra surface area makes a big difference.

“In the Woodford, some wells’ uplifts exceed 80%,” Montgomery illustrates. “That is unusual, but we frequently see 30%-40% uplifts and almost always can depend on 15%-20%. Those production increases can pay for the microproppant in 20 days.”

To achieve that uplift, he says the rock needs to have a hardness of at least 2.5 million modulus and contain natural fractures. Montgomery says most plays meet those criteria. “In fact, with the exception of the Marcellus, every well I have looked at has benefited from microproppant,” he assures.

How long the extra production takes to manifest can vary, Montgomery notes. An operator targeting Wolfcamp wells in the Midland Basin sees it in a month, but in other areas or formations, it may take three-six months. “In one case, the benefit did not appear for more than a year, but the wells with microproppant produced 81% more after three years,” he relates. “The microproppant has a compressive strength of 60,000 psi, so it can keep fractures open for a long time.”

Even much smaller production gains still can justify microproppant’s cost, Montgomery argues. “If it increases production 15%, that is enough to get the same amount of production out of four wells that normally will require five,” he says. “This lets operators boost production at a much lower capital cost.”

Mechanisms

In addition to directly propping fractures, microproppant may assist production in other ways, Montgomery suggests. Noting that it was developed as an industrial abrasive, he says the hard, spherical material can widen the fracture network through which it moves, allowing larger, more conductive 100 mesh to enter areas that otherwise will be too tight.

By scouring the rock, the microproppant also makes it easier for fluid to flow into perforations, Montgomery adds. He says data from numerous wells, including ones discussed in an article he wrote with Bill Strobel, shows that microproppant leads to more even fluid distribution.

Pressure data supports the concept that the microproppant clears a path. In most wells, the pressure required to put proppant away drops by 800-1,500 psi, Montgomery reports. “We have some operators who put microproppant on standby in case of screen-outs,” he mentions. “If they are struggling to inject proppant because a kink in the fractured tortuosity is causing high pressures, they will pump a slug of microproppant until they see a pressure drop, then put the job away. That immediate benefit comes alongside the long-term improvement of increased production.”

Sand Conveyor Belt

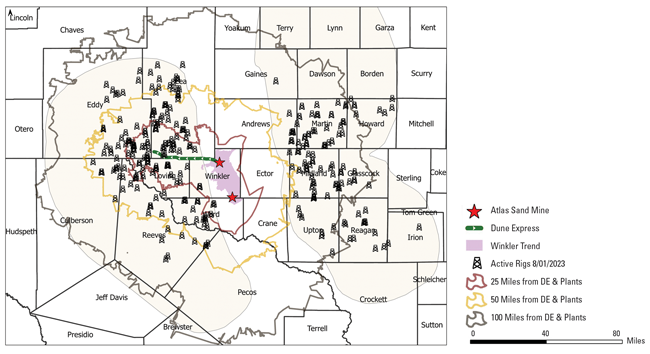

As the Permian Basin’s proppant demand continues to grow, so does truck traffic. “Sand demand and truck traffic have a linear relationship,” observes John Turner, president and chief financial officer of Atlas Energy Solutions, which operates two in-basin sand mines near the West Texas cities of Kermit and Monahans. “As an enterprise, we have been operating in the Permian for a long time. We have seen firsthand how much the additional traffic contributes to injuries, and even worse, fatalities.”

In the counties adjacent to the Texas sand trend, people are six times more likely to be involved in a fatal accident, Turner reports. “This is unacceptable,” he comments. “In the oil field, we have a long history of finding safer and more efficient ways to operate, which is why so much oil and water now moves by pipeline rather than truck.”

The Dune Express conveyor belt will carry high-quality sand from Atlas Energy Solutions’ mine in Kermit, Tx., to the heart of the Delaware Basin. By limiting how far trucks need to travel, Atlas says the conveyor belt will help prevent accidents while reducing costs.

To bring similar safety and efficiency to proppant transportation, Atlas is building the Dune Express, a 42-mile conveyor belt that begins at its Kermit facility and extends into New Mexico. With the ability to move 1,800 tons of sand per hour at a speed of 10 miles an hour, the company estimates the belt will be able to transport more than 13 million tons of sand a year.

In addition to permanent load-out facilities at the Texas-New Mexico border and the conveyor’s end, Turner says Atlas will be able to pick up sand at any point along the belt. “By building the Dune Express, we are essentially moving our sand plant from Kermit into the middle of the Delaware Basin, much closer to where the sand is used,” he says. “On average, we think we will be able to reduce the number of miles driven on public roads by 70%.”

Shortening truck routes will shrink the delivered cost for sand, Turner reasons. If a route only involves private roads, he adds, the savings that come from shorter distances can be magnified by attaching two or three trailers of sand to each truck rather than one.

The groundbreaking for the Dune Express occurred in March. Turner indicates that the necessary rights of way to complete the project have been secured. “When we first began talking with landowners, we had some interesting discussions,” he recalls. “However, as we moved through the negotiations, people became comfortable with the conveyor belt. Many of the surface owners realize it will encourage development of their minerals, and most live in the community and want to make the roads safer.”

Long-Term Design

The belt’s design minimizes any associated inconveniences it poses, Turner assures. For example, it includes crossings for cattle and wildlife, and it will pass over public roads at an elevation of 25 feet, several feet beyond the 18.5-foot height required by the Texas Department of Transportation.

The conveyor belt curves upward with the sand in the middle, but it still needs covers to protect the sand from the Permian’s high winds and unpredictable weather. According to Turner, Atlas conducted extensive testing to ensure these covers would keep proppant on the conveyor belt. “We spent a lot of time doing tests to get the right design for the cover,” he details.

“Once we had a design that could hold the sand, we took a prototype to the state of Washington and conducted more extreme tests,” he continues. “That involved setting up the prototype at various angles in front of a jet engine to simulate wind while using a fire hose to simulate rain. Even with the equivalent of tropical force winds, the proppant stayed on the belt and remained dry.”

Although they have not yet been applied to proppant transportation, conveyor belts have long carried other aggregate materials in the United States and abroad, Turner says. As it designed the Dune Express, Atlas tried to incorporate lessons learned from previous projects. “One of the most important components in a conveyor belt is the belt itself,” he notes. “To minimize wear and tear on the belt, it’s placed on idlers that roll to keep it moving. When those idlers start failing or get a little out of line, the belt sees unnecessary friction or tension.

“In the past, a conveyor operator would ride up and down the line and listen for the sound of an idler going out. You can imagine how efficient and reliable that was,” he describes. “Instead, we are using smart idlers that can alert our control room in Austin, Tx., when they are about to fail, which will let us send someone out to replace the idler while the belt keeps moving.”

In late July, Turner indicated the conveyor belt was on schedule to enter service toward the end of 2024. “It is getting a positive reception not only from operators but also from community leaders and legislators,” he says. “Everybody is excited about the chance to reduce traffic and accidents while simplifying proppant delivery.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.